Embrace REALvision software

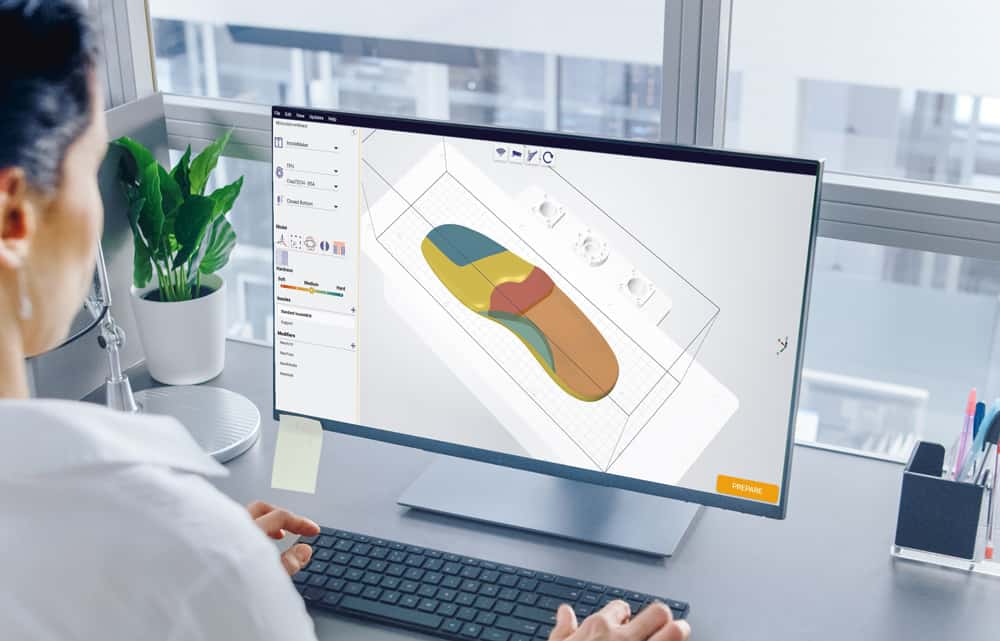

Prepare the insoles for printing by easily applying soft and hard zones for pressure relief and enhanced comfort

Prepare the insoles for printing by easily applying soft and hard zones for pressure relief and enhanced comfort

Bring your orthopedic expertise into the digital age and manufacture in-house

REALvision Embrace CAM software enables a streamlined single workflow to produce your products. The production process of a 3D-printed insole involves three steps:

Create a 3D model to generate the design file.

Input sources can include a foam impression kit, 3D scanner, pressure mapping, or parametric data.

Use the software to easily add soft and hard zones precisely where needed, with an intuitive slider.

Our patented technology seamlessly incorporates gradients between these zones.

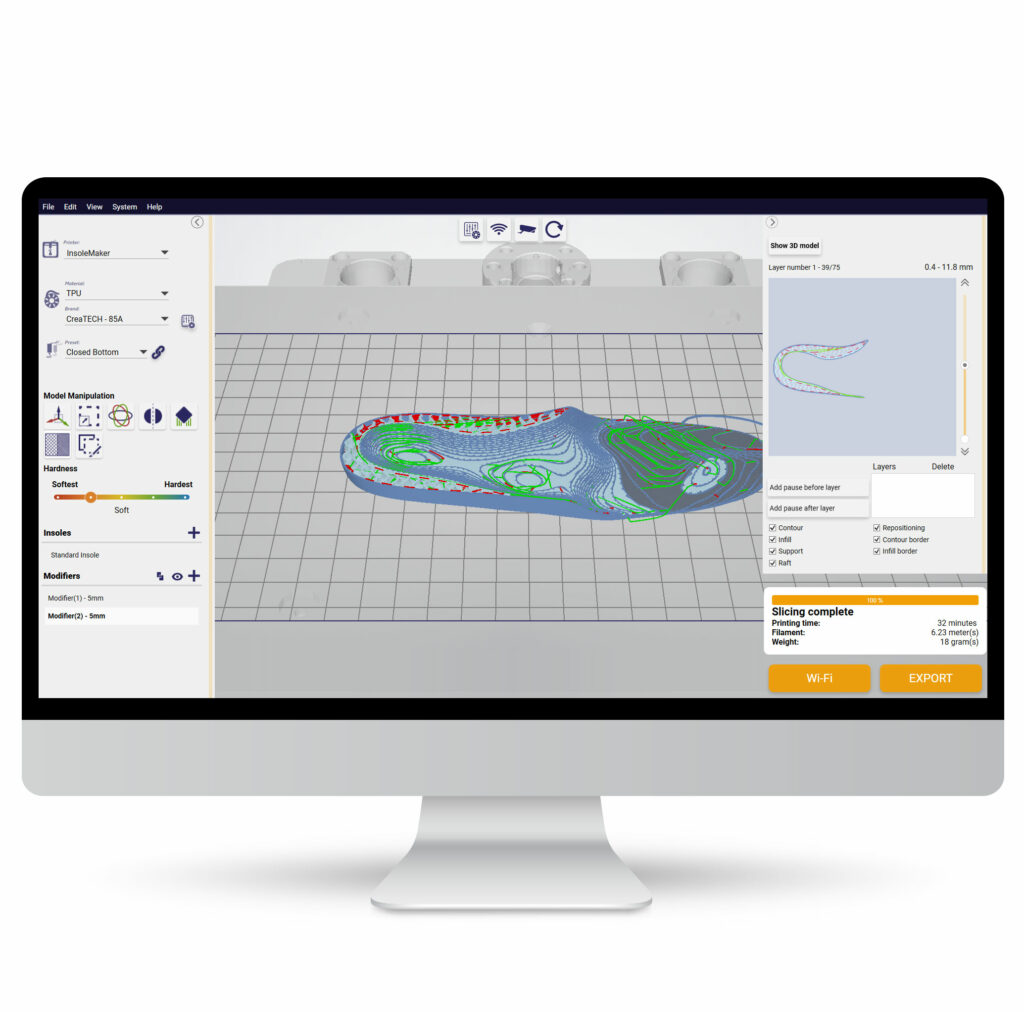

Prepare, preview, and print your model.

Gain a precise estimation of the printing time and material usage.

”I like the paint-on modifiers feature. It lets me paint easily on a model and create modifiers without opening CAD and spend time on creating shapes there. It saves a lot of time.”

Iryna Shulha, Print Service Operator

The modifiers features in REALvision Embrace CAM software enable you to take full control of the internal regions of your products and incorporate customized gradient zones freely and simply. There are three ways to do this:

REALvision Embrace CAM software enables you to prepare your object with precise printing time and accurate material estimation.

Planning production time is essential for precise scheduling, maximizing throughput, and customer care. With REALvision Embrace software you will know the actual print time that is based on calculation and not on assumptions.

Do you have more machines working in production? REALvision Embrace CAM software enables 24/7 production without human interaction: