Rigid spinal brace

Correction and comfort go hand-in-hand; orthopedic braces are taken to a new level with 3D printing. Add digital design and multi-stiffness zones to your workflow for braces that fit better, work better, and look better.

Comfort

Lightweight

Cost-effective

- Reduce physical storage: No more shelves of molds—the digital model is safely stored on your server.

- Replicable: Need a second brace? Simply reprint or adjust the original file—no need to start over.

- Easy mounting: Integrate bolt-ready areas directly into the design to easily install straps or closures.

- Minimal material waste: Our digital process eliminates offcuts, supporting your sustainability goals.

- Precise design: Additive manufacturing builds the brace layer by layer, unlocking new levels of design accuracy.

- Better aesthetics: 3D printed braces can have a cleaner, more modern look, especially relevant for adolescent users.

- Patient engagement: Patients are likelier to wear comfortable braces and look good; customization options can improve compliance.

- Scalability: Once the process is set up, scaling production across multiple clinics or locations is easier with digital workflows.

Designs that deliver

Discover how professionals use our technology to treat spinal conditions—delivering better outcomes for their users, with precision and confidence.

Real-world results: 3D printed brace helps Astrid keep an active life

What happens when technology meets persistence? Astrid’s story is a powerful example. Diagnosed with scoliosis at 13 and told that surgery was her only option, she chose a different path. Eleven years later, she became one of the first in Denmark to try a 3D printed spinal brace, custom-fitted to support both curve and rotation correction.

Her case highlights what’s possible when orthopaedic expertise, digital design, and personalized treatment come together. The brace was developed by the team at Dansk Skoliosecenter and orthopaedic engineer Thomas Borregaard, using a workflow that offers flexibility not just in the brace, but in how care is delivered.

From improved spinal alignment to the ability to stay active, this case shows that bracing can be part of a non-surgical treatment option even in adulthood. Astrid’s experience speaks to the power of individualized solutions for managing spinal curvature and postural challenges, without compromising quality of life.

Imagine what you can do for your clients

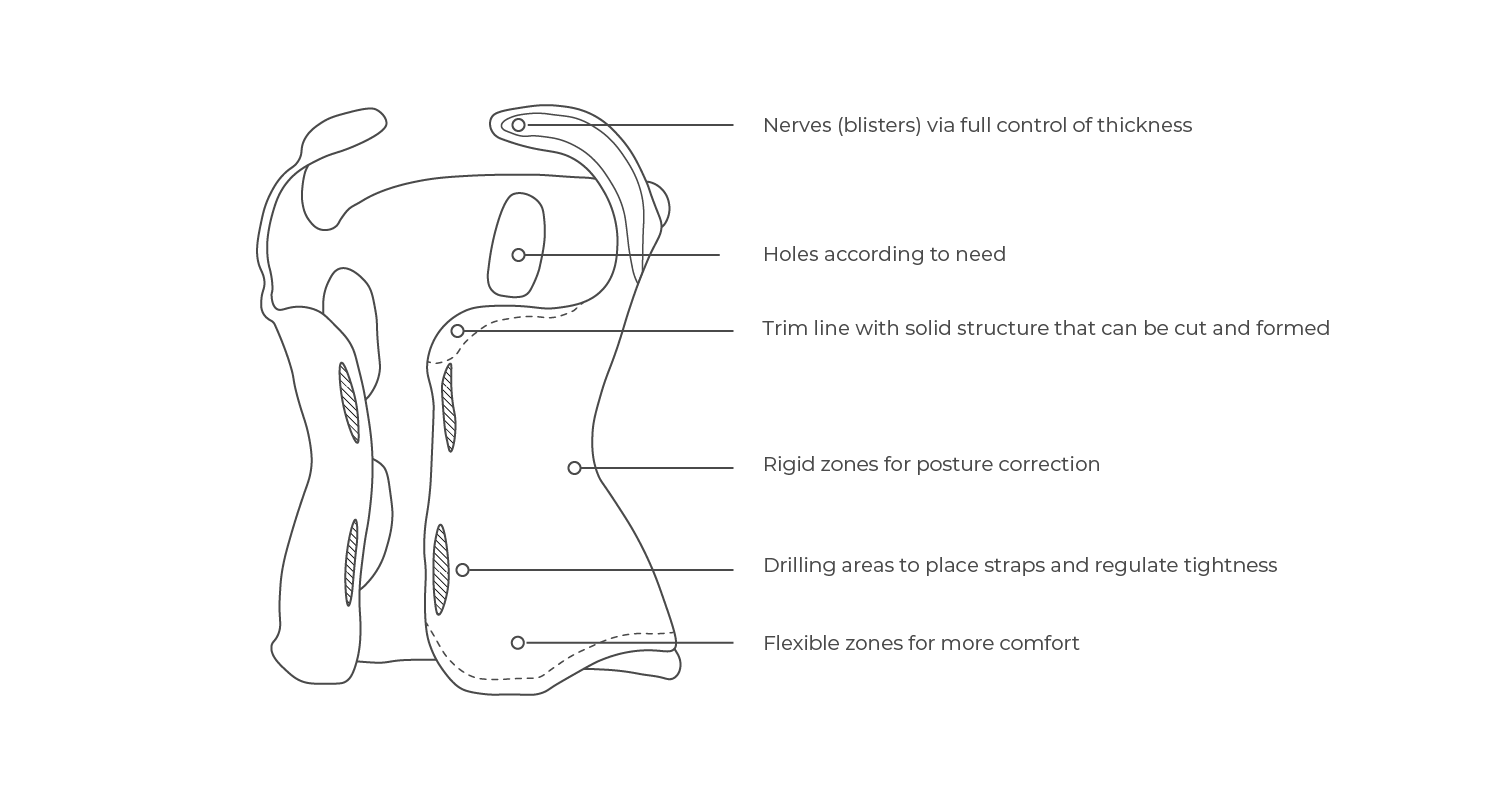

With multi-stiffness design, we enable you to create orthopedic corsets and spinal braces tailored to conditions such as scoliosis, kyphosis, and vertebral fractures—delivering an optimal balance of correction, support, and comfort.

A new approach to spinal bracing

3D printing is reshaping how spinal braces are made, offering orthopedic professionals a way to create braces that are lighter, more comfortable, and better tailored to each patient’s anatomy. Whether you’re treating scoliosis, kyphosis, or vertebral fractures, this technology makes it easier to design around the individual’s spine curvature, posture, and mobility needs.

Designed for comfort, precision, and clinical results

Braces can now be designed with areas of different stiffness in a single structure, supporting the spine where stability is needed while offering flexibility where comfort matters. This is especially useful for managing conditions like adolescent idiopathic scoliosis, degenerative changes in the lumbar spine, or recovery after spinal surgery. The result is a brace that not only fits better but also improves patient compliance and outcomes.

Create a better correction today

From digital model to physical brace

A digital workflow means no physical molds to store, no manual shaping, and far fewer material offcuts. Once a scan or measurement is taken, the brace can be designed and printed with high precision, including mounting points for straps or customized support zones. This process makes it easier to make adjustments, reprints, or replacements, especially useful when treating growing children or patients who need multiple braces over time.

Seamless onboarding and expert support for your 3D printed spinal braces

Transitioning to 3D-printed orthopedic braces can feel complex, but we’re here to make it straightforward. Our onboarding process is designed to support you every step of the way, whether you want to use our 3D print service or manage production in-house with our system.

Starting with comprehensive design guides, we share industry best practices to help you create precise, patient-specific braces that leverage the full advantages of 3D printing. These guides include step-by-step instructions and tips on how to apply multi-stiffness zones, optimize material use, and integrate mounting features, helping you maximize correction, comfort, and durability.

Our expert team is also available to review and verify your digital files before printing. This service ensures your brace designs meet technical requirements and quality standards, reducing errors and saving valuable time.

Best of all, you don’t need to be a 3D printing specialist to benefit from this technology. We adapt our support and communication based on your experience level, offering a smooth, clean workflow that fits your existing clinical and production routines.

With this approach, you can confidently innovate your orthopedic offerings, improve patient outcomes, and streamline your workflow—all while maintaining full control over design and production quality.

Print on demand or power your own production line

3D print service

Production solutions

Supporting both simple and complex cases

3D printed spinal braces can be used across various clinical cases—from mild posture correction to complex deformities linked to congenital or neuromuscular conditions. In more severe cases, where traditional bracing can feel bulky or uncomfortable, additive manufacturing opens the door to thinner, more breathable structures that patients are more likely to wear consistently.

A smarter workflow—fewer steps, more control

Move from plaster and plate to a fully digital workflow that keeps things simple and scalable. Scanning replaces casting. Digital modeling replaces manual cutting. And once your design is ready, it can be printed with precision and minimal waste. This not only saves time, it also reduces the number of iterations and lets you make changes faster.

Put your clinical expertise at the center of the design process

Orthopedic professionals understand the complexity of spinal alignment and correction. With a digital, 3D printed workflow, you can turn that knowledge into precise brace designs, customized to the individual spine curvature, posture, and condition severity. Whether addressing scoliosis, kyphosis, or post-operative support, you remain in full control of the corrective strategy and design choices.

Design with confidence—deliver with consistency

Each brace is produced from your digital file, meaning it’s replicable, adjustable, and easy to store or retrieve. Need a second brace after a growth spurt or surgery? No need to start over. You get full traceability and a consistent result every time, improving your clinical outcomes and workflow efficiency.

Optimize correction and comfort with multi-stiffness zones

The multi-stiffness design allows you to adjust support levels across the brace, rigid where stability is needed, and softer where comfort matters. This opens up new opportunities for fine-tuned bracing strategies that adapt to your patient’s anatomy and clinical goals, whether it’s for pediatric scoliosis or post-fusion stabilization.

Frequently asked questions about spinal braces and 3D printing

What conditions can spinal braces help manage?

Spinal braces are often used to help manage conditions such as scoliosis (including adolescent idiopathic scoliosis), kyphosis, and other types of spinal curvature. They may also be part of the care plan for people recovering from spinal surgery or dealing with conditions like degenerative scoliosis or vertebral fractures. The exact treatment plan depends on the patient’s diagnosis, anatomy, and medical guidance.

How are 3D-printed spinal braces different from traditional ones?

3D printed braces are digitally designed based on scans or measurements, allowing for a precise fit and a more consistent production process. They can be made with varying stiffness levels in different areas, offering support and comfort where needed. This design freedom can lead to lighter, more breathable braces that patients are more likely to wear consistently.

Can 3D-printed braces be used after spinal fusion surgery?

Yes—3D printed spinal braces can be designed to support the spine after surgical procedures like spinal fusion, laminectomy, or discectomy. They can help stabilize the fused area, limit unwanted motion, and support healing. Your healthcare provider will decide whether bracing is necessary after surgery.

What areas of the spine can a brace support?

Depending on the design, a spinal brace can support the thoracic, lumbar, or cervical spine, or a combination of regions (such as thoracolumbar). The goal is to address the specific area affected by curvature, instability, or recovery needs.

Are these braces suitable for adults and children?

Yes. Spinal braces can be used for both adults and children, though the design will vary based on growth, spine maturity, and the underlying condition. 3D printing allows for easy customization, which is especially useful during adolescence or in progressive conditions that require brace updates over time.

What is the workflow for creating a 3D printed brace?

The process starts with either a scan, x-ray, or a manual measurement of the patient’s torso. From there, a digital model is created and adjusted using specialized software. Orthopedic professionals can apply their knowledge to refine the design, choosing where to add support or flexibility. Once finalized, the brace is printed, finished, and prepared for fitting.

How are multi-stiffness zones used in 3D printed braces?

Braces made with multi-stiffness zones can offer rigid support in some areas (for structural correction) and softer zones in others (for comfort and movement). This flexibility can improve how the brace fits and feels, while still meeting clinical goals such as limiting curve progression or supporting post-surgical alignment.

What material is the 3D-printed brace made from?

Our braces are printed in polypropylene—a material already widely used in traditional orthopedic corsets. It’s known for being lightweight, durable, and skin-friendly. The same base material is used in many medical and even food-safe applications, and it meets international standards for safety and quality. This ensures that the braces are both functional and comfortable to wear over long periods.

Is the 3D printed material safe for skin contact?

Yes. The polypropylene we use is certified for food safety and medical use, making it suitable for prolonged skin contact. It’s also easy to clean and resistant to moisture and sweat, which helps improve hygiene for daily wear.

Can a 3D-printed brace address spinal rotation as well as curvature?

Yes—many spinal conditions, such as scoliosis, involve both a sideways curve and a rotation of the vertebrae. With digital design and 3D printing, the brace can be customized to apply targeted pressure where needed, based on the curve’s shape, location, and rotation. This level of precision supports the clinical goals set by the orthopedic professional while ensuring a better fit and improved comfort.

What is meant by “curve correction” in a spinal brace?

Curve correction refers to the brace’s ability to support and guide the spine toward a more natural alignment. While braces don’t “straighten” the spine permanently, they can help slow or stop the progression of spinal curves, especially in growing children. A well-designed brace applies controlled pressure in specific zones to encourage better posture and limit worsening over time.

How do I get started with 3D-printed spinal braces?

Getting started is simple and tailored to your needs. Whether you choose our full 3D print service or prefer to work with our production system, we provide a complete onboarding flow to make the process easy and efficient. This includes detailed design guides, best practices, and expert support. Our team reviews your digital files before printing to ensure quality and accuracy, so there’s no need to be a 3D printing expert. We adapt the process based on your experience level, helping you confidently integrate 3D printed braces into your workflow.