How Multhoff modernized diabetic care with Cubix 3D-printed custom insoles

Multhoff GmbH & Co. KG is a trusted orthopedic workshop specializing in handmade custom diabetic insoles and orthopedic shoe solutions. For years, their team relied on traditional craftsmanship; from foam-box impressions and plaster models to hand-layered, milled orthotic builds. While effective, the process was time-consuming and left limited room for fine biomechanical adjustments.

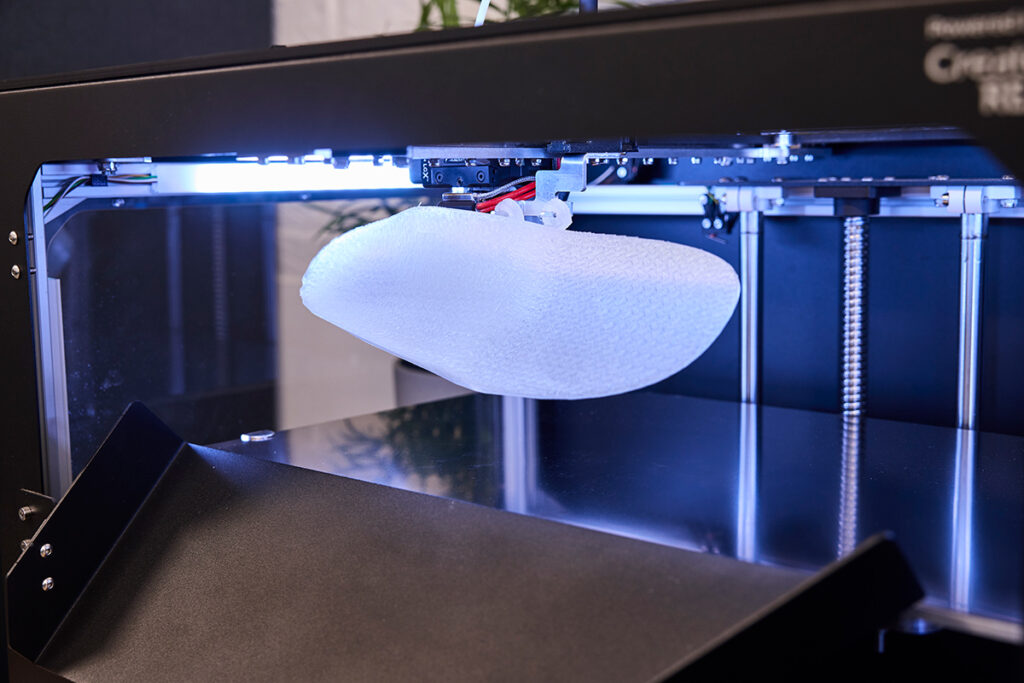

For patients with diabetes and sensory loss, precise pressure-relief insoles and highly accurate custom orthotics are vital. Even small pressure peaks can lead to ulcers, infections, or long-term complications. Multhoff wanted to evolve their workflow with a solution that delivered higher precision, safer offloading, and faster turnaround times without compromising the handcrafted expertise quality they value.

Moving from traditional craftsmanship to a digital workflow

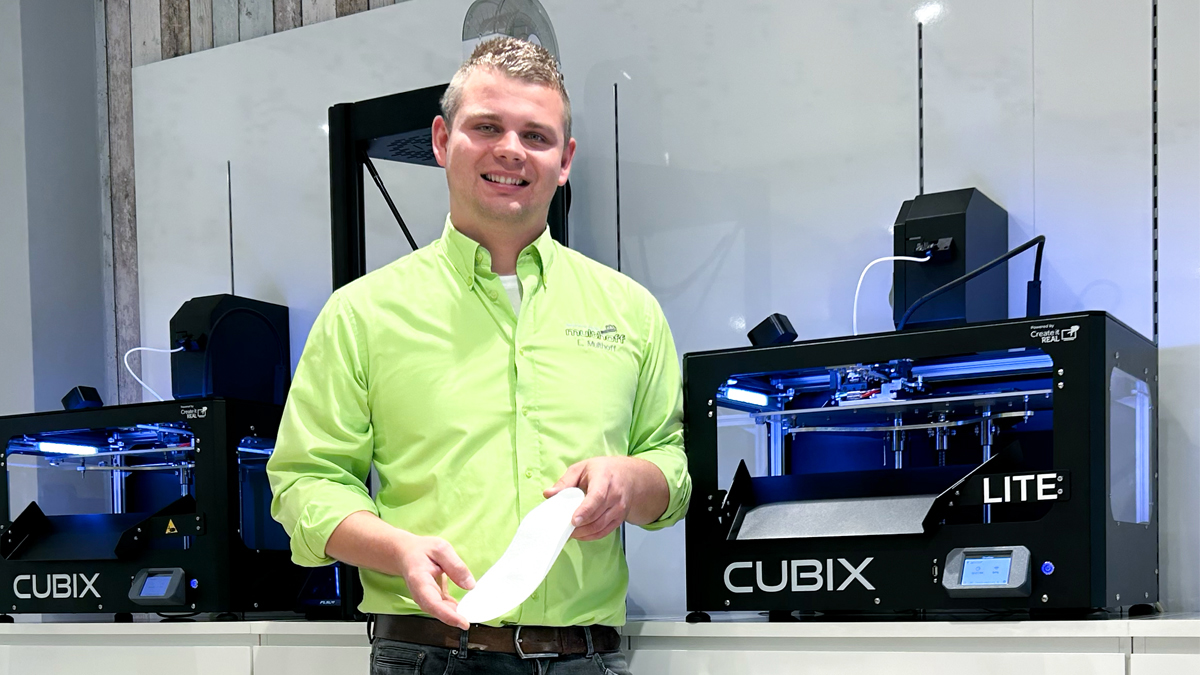

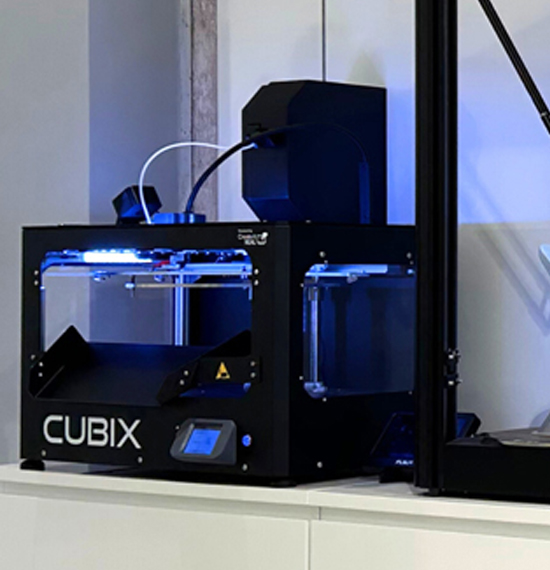

Facing the limitations of traditional manual methods, such as time-consuming plaster models, hand-layered insoles, and the difficulty of making precise adjustments, Multhoff gradually upgraded their production process to a fully digital workflow. By integrating the CUBIX printer, GP Radix foot-pressure measurement, OptiCAD for final construction, and InsoleCAD for insole design, the team gained the ability to produce custom insoles and orthopedic shoes with greater precision, repeatability, and efficiency.

“CUBIX insoles are not an off-the-shelf solution, but true craftsmanship — individually made for you and your feet. We rely on sustainable, recyclable materials and high-quality manufacturing so that you can take every step in comfort and with a clear conscience. CUBIX by go-tec is individual, sustainable, and high-quality.”

— Lukas Multhoff

- Faster iteration: 3D printing enabled prototypes to be tested before the final product, saving time and reducing errors.

- Greater consistency: Digital design and printing ensured that each insole or last met exact specifications.

- Precise biomechanical control: Variable stiffness and targeted adjustments can be digitally implemented, enabling more sophisticated pressure distribution and support.

- Cleaner, more sustainable production: Less reliance on manual cutting and glueing reduces material waste and reliance on external suppliers.

Elevating custom insole manufacturing through digital craftsmanship

- Increased productivity.

- Reduced material waste.

- Improved clinical accuracy.

- Reduced manual adjustments.

- Elevated patient comfort and safety.

The combination of precise digital design and 3D printing strengthened both clinical results and daily practice, making care more modern and effective. More personalized than ever before. Let’s review a special patient case from Multhoff.