Providing safe pressure distribution for a high-risk diabetic foot

We follow a patient of Molthoff who is living with Type II diabetes and polyneuropathy. Reduced sensitivity in the feet meant that pressure points often went unnoticed, while an unsteady gait created constant micro-loads in vulnerable areas. Together, these factors increased the patient’s risk of developing ulcers. Injuries that can escalate quickly and, in severe cases, lead to hospitalisation or even amputation.

To prevent this, the clinical team needed a solution that combined accuracy, safety, and reliable offloading. The patient required:

- Custom diabetic insoles with highly controlled pressure distribution.

- Reliable offloading insoles to protect pressure-sensitive areas.

- A therapeutic orthopedic shoe that could support and guide the gait.

- A workflow that allowed for precise early adjustments before finalising the device.

Traditional manual methods could address some of these needs, but they also had limitations. Foam impressions, plaster models, and hand-layered insole builds allow for variation, and even minor variations can make a significant difference for a high-risk diabetic foot. Multhoff therefore introduced a method for producing custom insoles and footbeds that were safer, more consistent, and easier to fine-tune throughout the treatment process.

“I have diabetes and have always had problems with pressure points. Since being fitted with 3D-printed insoles and a specialized therapeutic shoe, I rarely develop new pressure points. The fit is perfect.”

— Patient

Applying the workflow to a high-risk patient

For the patient we follow, living with Type II diabetes and polyneuropathy, this workflow had a direct impact. A 3D-printed digital last enabled the team to produce a test shoe early in the process, allowing them to assess fit, gait, and pressure distribution long before the final orthopedic shoe was manufactured.

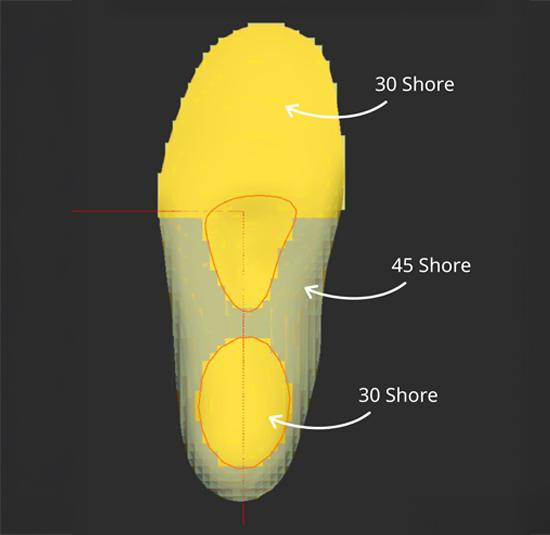

Next, a custom 3D-printed Cubix supplement was designed for the shoe. With variable stiffness zones, the team could:

- Cushion sensitive areas.

- Stabilize the foot during gait.

- Target pressure relief exactly where it was needed.

- Offload critical regions to prevent ulcers.

This precise, personalized approach, made possible by the digital workflow, allowed Multhoff to provide safer, more effective, and better-fitting custom diabetic insoles and orthopedic shoes for the patient.

Fast iterations and precise adjustments

The implementation began by capturing the patient’s foot geometry and importing it into the digital design environment. Using this data, the team created a digital last that reflected the patient’s exact anatomy. A test shoe was then printed to evaluate the fit, gait, and pressure distribution before producing the final orthopedic shoe.

This early testing enabled rapid corrections without remaking molds or starting from scratch. The team could fine-tune the shoe and insole designs with precision, ensuring the final product met both clinical requirements and patient comfort.

When designing the Cubix supplement, the team experimented with different stiffness zones to identify the optimal configuration for cushioning, stability, and pressure relief. Close collaboration between technicians and clinicians ensured that sensitive areas were protected and that the gait was stabilized.

After delivering the final orthopedic shoe, an in-shoe pressure measurement confirmed that the design worked as intended. Pressure was reduced in critical regions, validating both the digital design and the chosen biomechanical strategy. The workflow enabled rapid, confident adjustments, thereby making the treatment safer and more predictable.

Improved safety, efficiency, and patient satisfaction

The feedback from the patient is clear: “I have diabetes and have always had problems with pressure points. Since being fitted with 3D-printed insoles and a specialized therapeutic shoe, I rarely develop new pressure points. The fit is perfect.”

The digital workflow with the Cubix 3D printing system produced both clinical and operational benefits.

- Perfect anatomical fit: Custom insoles matched the patient’s foot shape precisely.

- Targeted pressure relief: Variable density zones protected vulnerable areas with high accuracy.

- Faster production: 3D-printed insoles can be produced significantly faster than traditional hand-layered builds.

- Cleaner and more sustainable manufacturing: Reduced reliance on external suppliers and less material waste.