3D Printing with soft and flexible materials

We are your facilitator to unlock the benefits of 3D printing with soft, elastic, and flexible materials.

With a customized printing strategy we help you leverage your products.

The advantages include:

- Superior prints of medical-grade customized devices.

- Saving time in the production process.

- Skipping the molds and excessive waste.

Recycling scheme

Programmable zones

Replace traditional foam

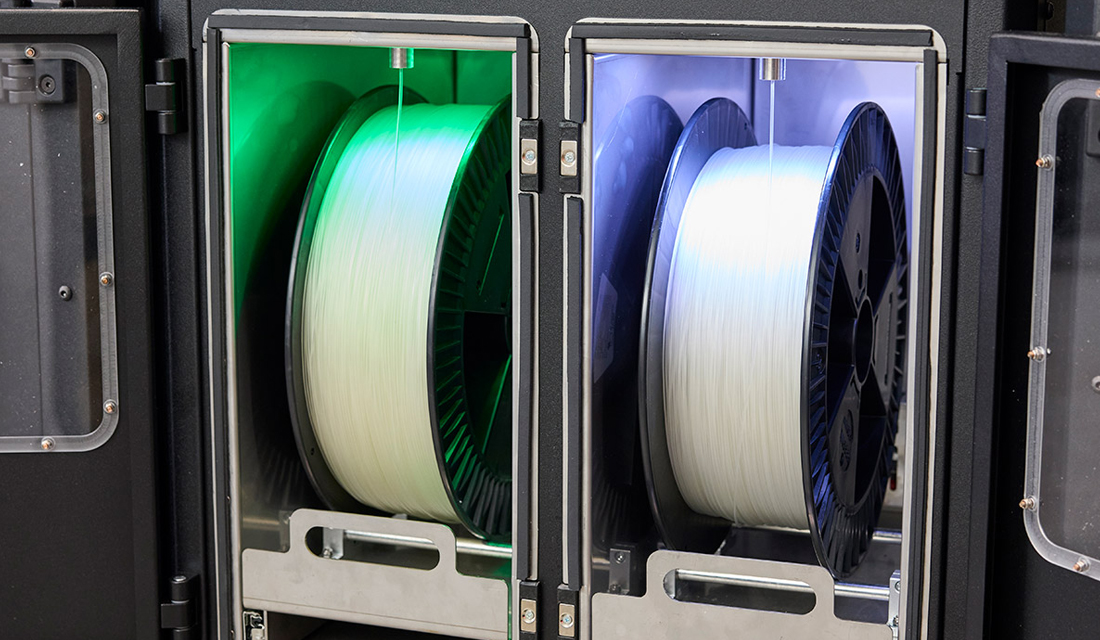

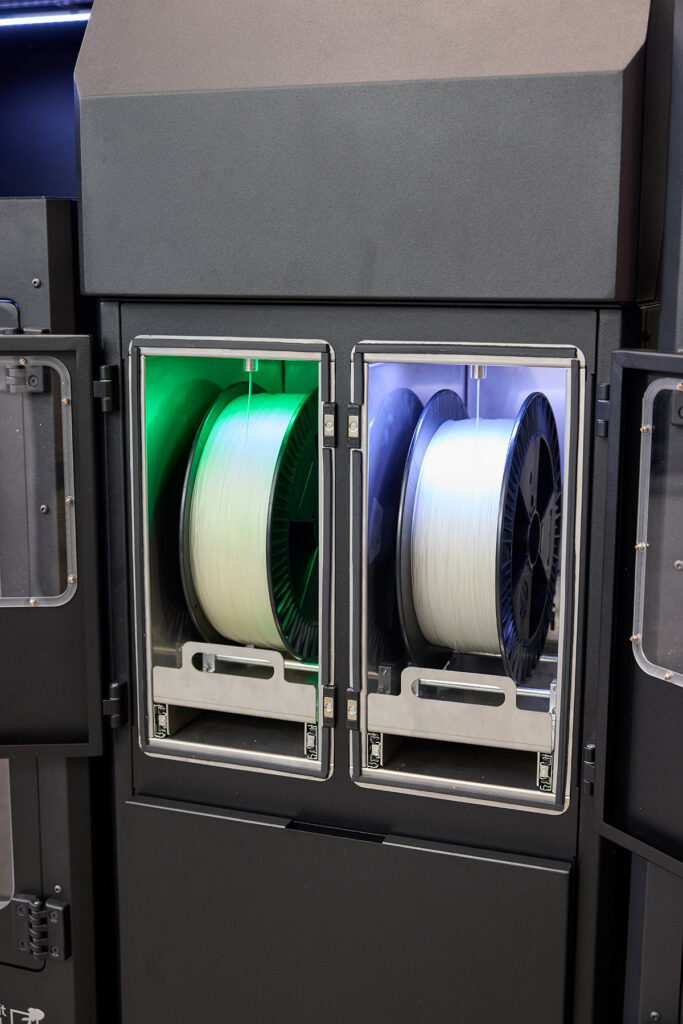

Printed in flexible TPU material

We have developed our special 3D print filament made from flexible TPU (Thermoplastic polyurethane) material to optimize the printing results and properties. The outcome is a product that is washable and fire retardant (comply with EN 1021-1 and EN 1021-2).

From a manufacturing point of view, using the printing process limits the waste to zero. With a recycling scheme of TPU-based products, the environmental footprint is reduced significantly compared to traditional foam products.

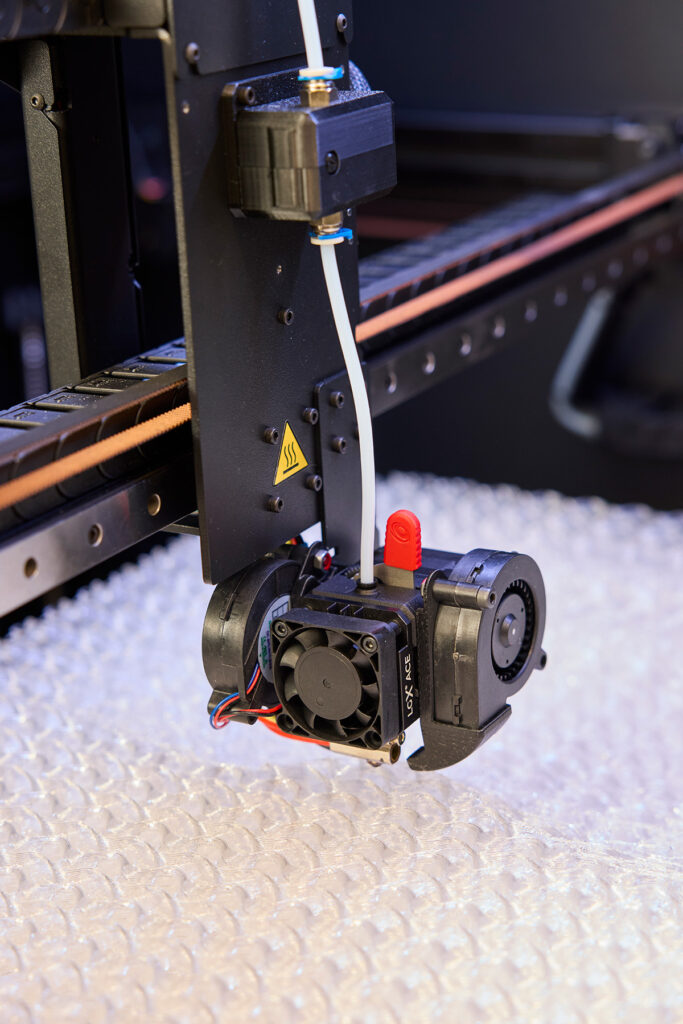

Another advantage of using additive manufacturing technologies with melting plastic parts as infill is to ensure a no-dust production environment. There is no hindrance to operating the 3D printing production in a standard office environment.

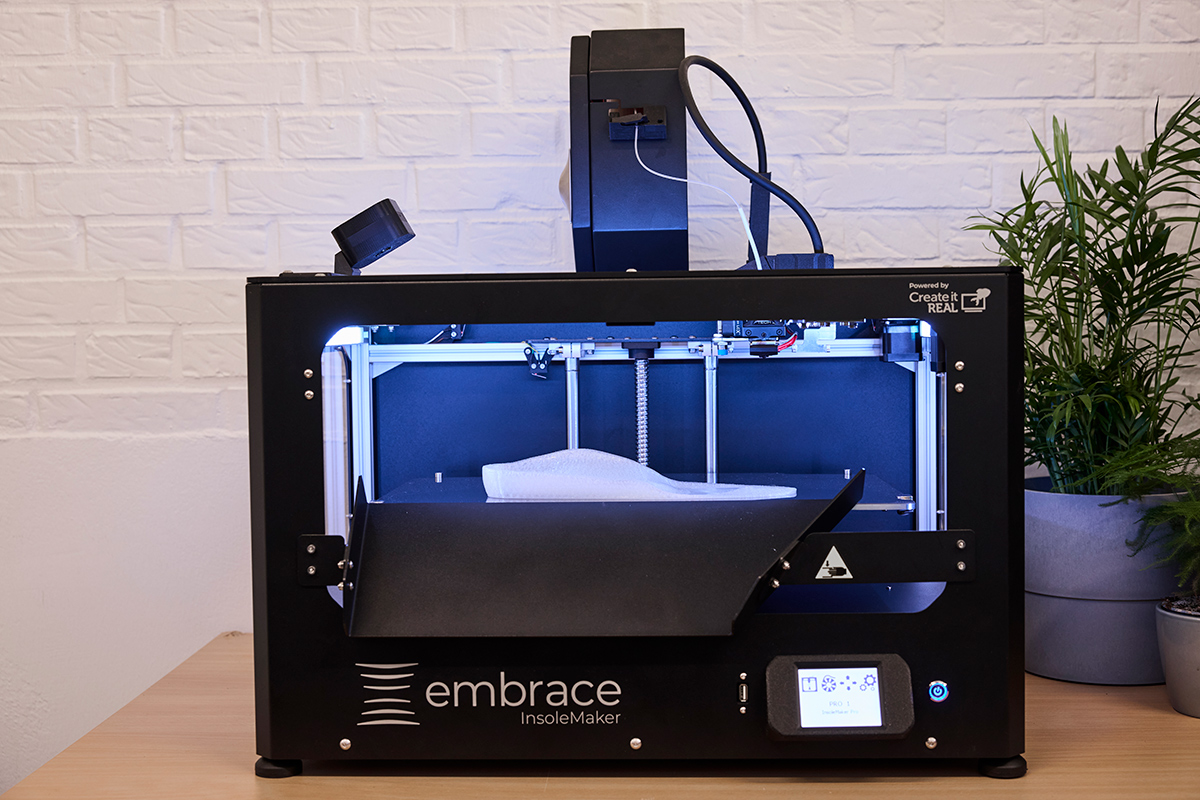

Customized printing of insoles

Individually customized insoles that fulfill the requirements of persons with foot problems require expertise and in-depth knowledge to produce.

Traditionally, the production process involves manual work and a high percentage of wasted material. Our solution for 3D printing insoles comprises an effortless operation, and we use 100% recyclable filaments. Our partner Marcel Domenghino, CEO of GeBioM says:

“Together with Create it REAL we can offer an integrated process from scan to printed insole. Reducing manual work and the need for technical know-how.“

"Thermoplastic polyurethane, popularly referred to as TPU, is a great material to work with. It has several unique properties, such as elasticity, that add flexibility to the printed part. Furthermore, it is resistant to oil and grease, making it an excellent choice for orthotic applications and their users. For O&P devices, we choose to work with a clear and transparent TPU, certified internally and externally."

— Jeremie Pierre Gay, CTO and Founder of Create it REAL

What does it take to get started?

A range of flexible filaments and materials is available, ranging from slightly bendable to liquid. Many of these are great fits for customized products and medical devices.

Getting started with 3D printing in flexible materials can be challenging, as this usually requires a dedicated set-up with the right 3D printer, software, and a thought-through printing strategy.

We can help you build a solution that makes printing in elastic and flexible materials like TPU, fluids, and silicones easy and match expectations. We can provide you with highly advanced and user-friendly software, and at the same time, we hide the complexity so that all team members can operate it.

8 good reasons to use CreaTECH soft TPU for orthopedic products

By leveraging the benefits of soft TPU in orthopedic products, you can create solutions that prioritize hygiene, sustainability, and comfort, ultimately improving the overall well-being and satisfaction of patients.

Hygiene: Soft TPU is inherently hygienic due to its non-porous surface, which makes it resistant to bacteria, fungi, and other microorganisms. This quality is crucial in orthopedic products where maintaining cleanliness and preventing infections is essential.

Biocompatibility: Soft TPU is biocompatible, meaning it is safe for use in contact with human skin and tissues. This makes it an ideal material for orthopedic products as it minimizes the risk of allergic reactions and irritation.

- Customization: Our soft TPU can be easily shaped and printed to fit individual patients’ needs, providing personalized orthopedic solutions.

- Durability: Soft TPU exhibits excellent durability and resilience, allowing orthopedic products to withstand repeated use and maintain their shape over time. This extends the lifespan of the products, reducing the need for frequent replacements.

- Ease of maintenance: Soft TPU is easy to clean and maintain, enhancing the hygiene of orthopedic products. It can be washed or wiped down with mild disinfectants, making it convenient for regular use in medical settings.

- Shock absorption: Soft TPU has excellent shock-absorbing properties, beneficial for orthopedic products such as shoe insoles, cushions, and inserts.

- Moisture management: Soft TPU has moisture-wicking properties that allow it to manage moisture build-up effectively and prolong the life span of the printed object.

- Sustainability: Soft TPU is a more sustainable alternative than traditional materials used in orthopedic products. It can be recycled, reducing waste and minimizing environmental impact.