Ideas we already made REAL

Our customers bring us real-world challenges and invaluable expertise from their industries. We combine their innovative ideas with our technical know-how in 3D printing. Together, we transform visions into live automatic production systems or custom software solutions. Partnerships are crucial to our success and serve as vital allies in our journey.

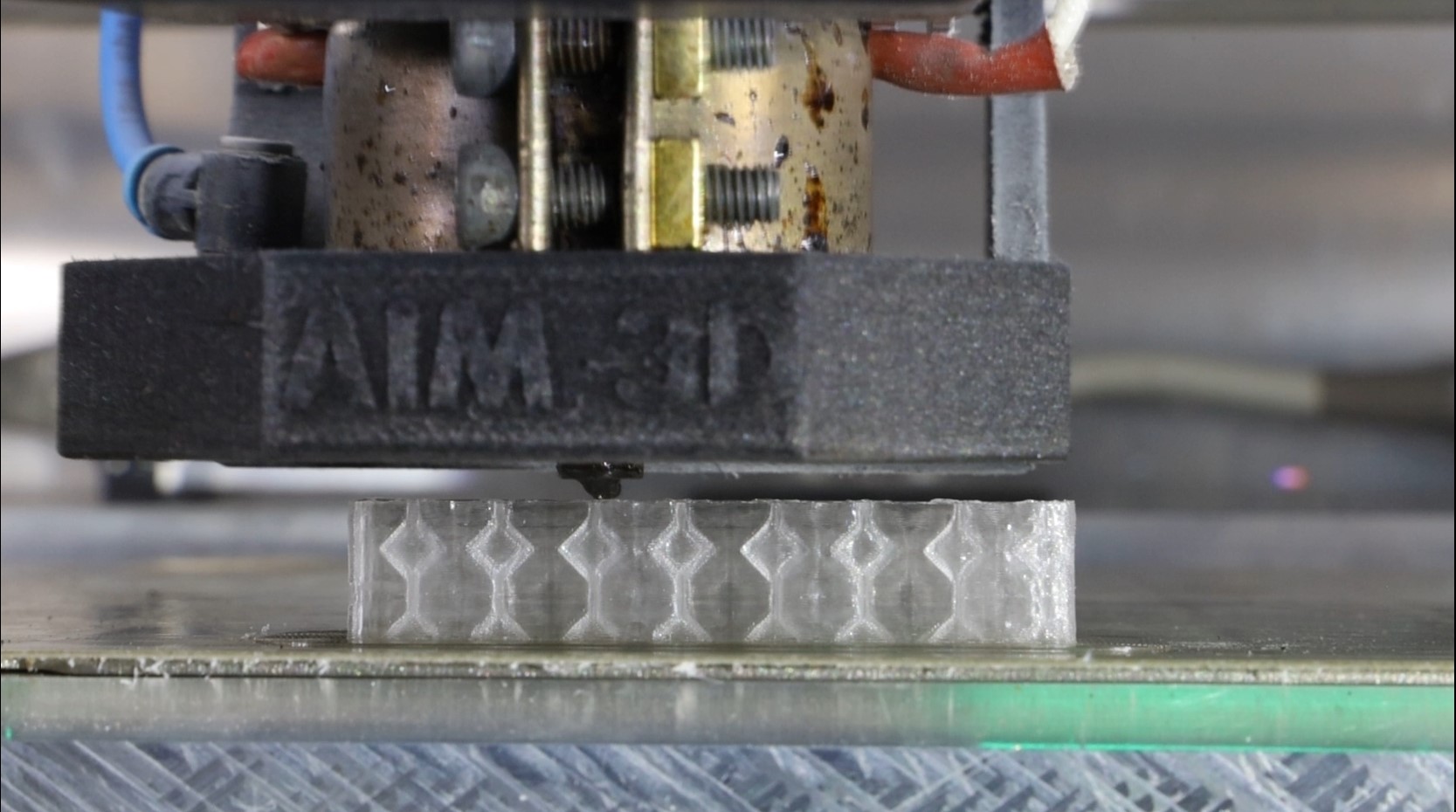

Programmable FoamⓇ our unique capability

How we transform and enrich traditional foam components

Programmable FoamⓇ offers an innovative alternative to traditional foam, enhancing the quality and versatility of the final product. Our patent-pending technology ensures unmatched performance.

- We enable your craftsmanship to go digital with a streamlined workflow for customized products

- Our high-quality 3D-printed foam is breathable, hygienic, and bio-compatible

- Programmable FoamⓇ ensures cushioning and comfort by effectively distributing and relieving pressure

Imagine what you can accomplish

Do you have an application and a vision for implementing 3D printing into your production flow? Reach out to us for a talk about your challenge.

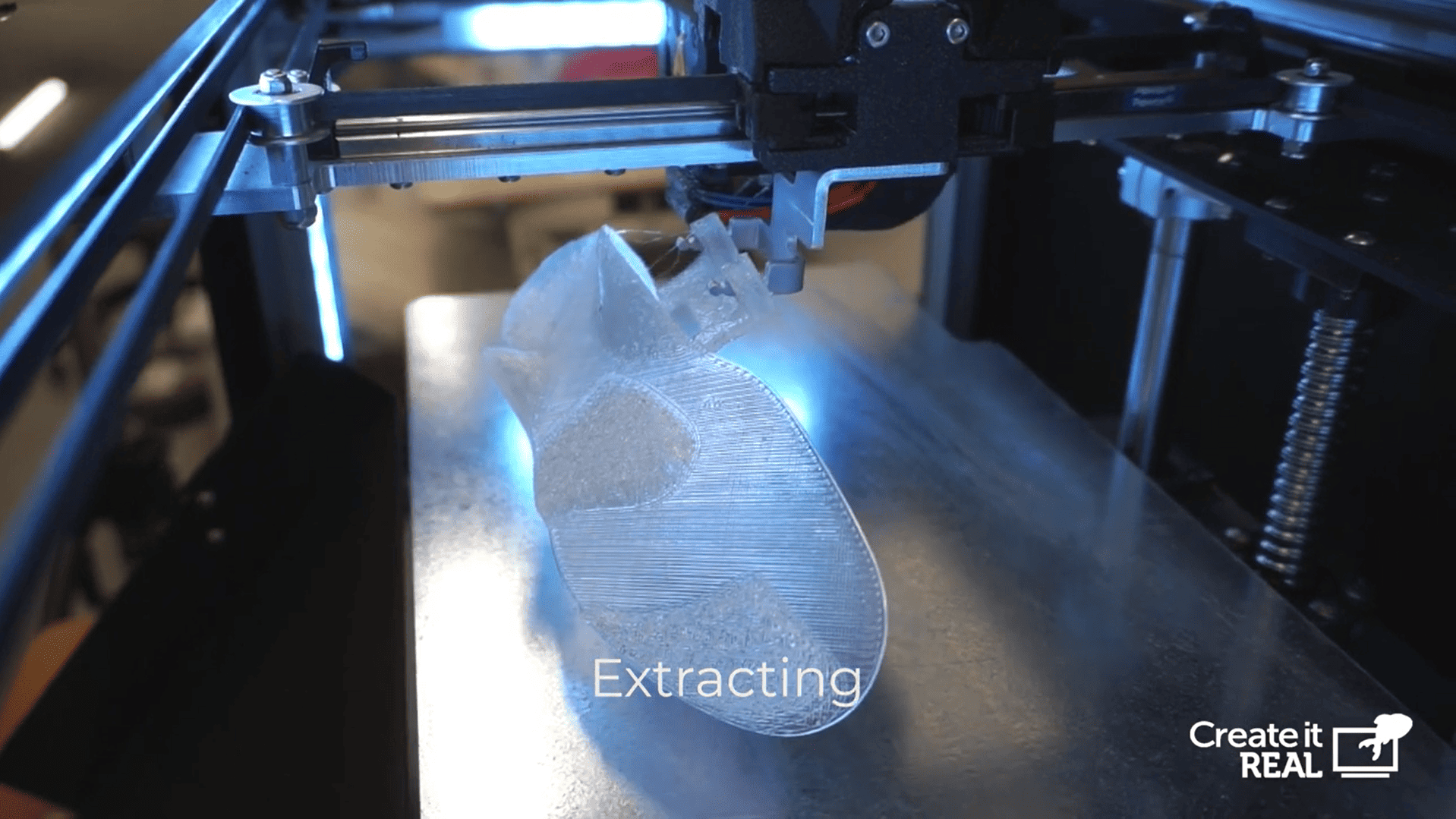

Automatic Extraction for continuos production

Efficient production of orthopedic insoles

The patent-pending automatic extraction option seamlessly enhances the Embrace Insole solution, enabling production to continue beyond regular office hours. With this advancement, the insole is automatically labeled, detached, and gently guided down a ramp into a designated box. A built-in camera diligently assesses the success of the extraction process.

Orthopedic solutions

Our Embrace product suite offers dedicated solutions for custom seating, corrective braces, and insoles. All our business solutions are developed with the final product and the end-user’s comfort in mind. There is no need for prior knowledge of 3D printing, as the solutions are easy to operate, and our team of experts is with you.

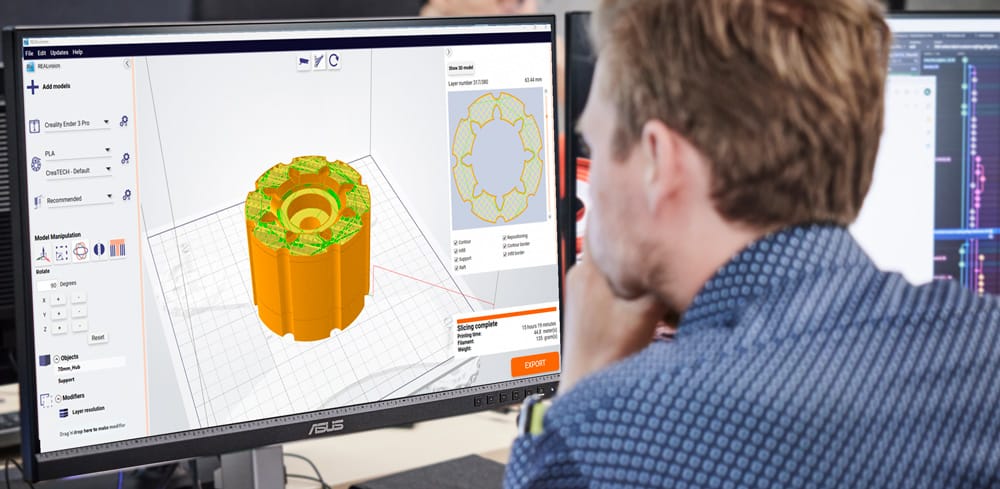

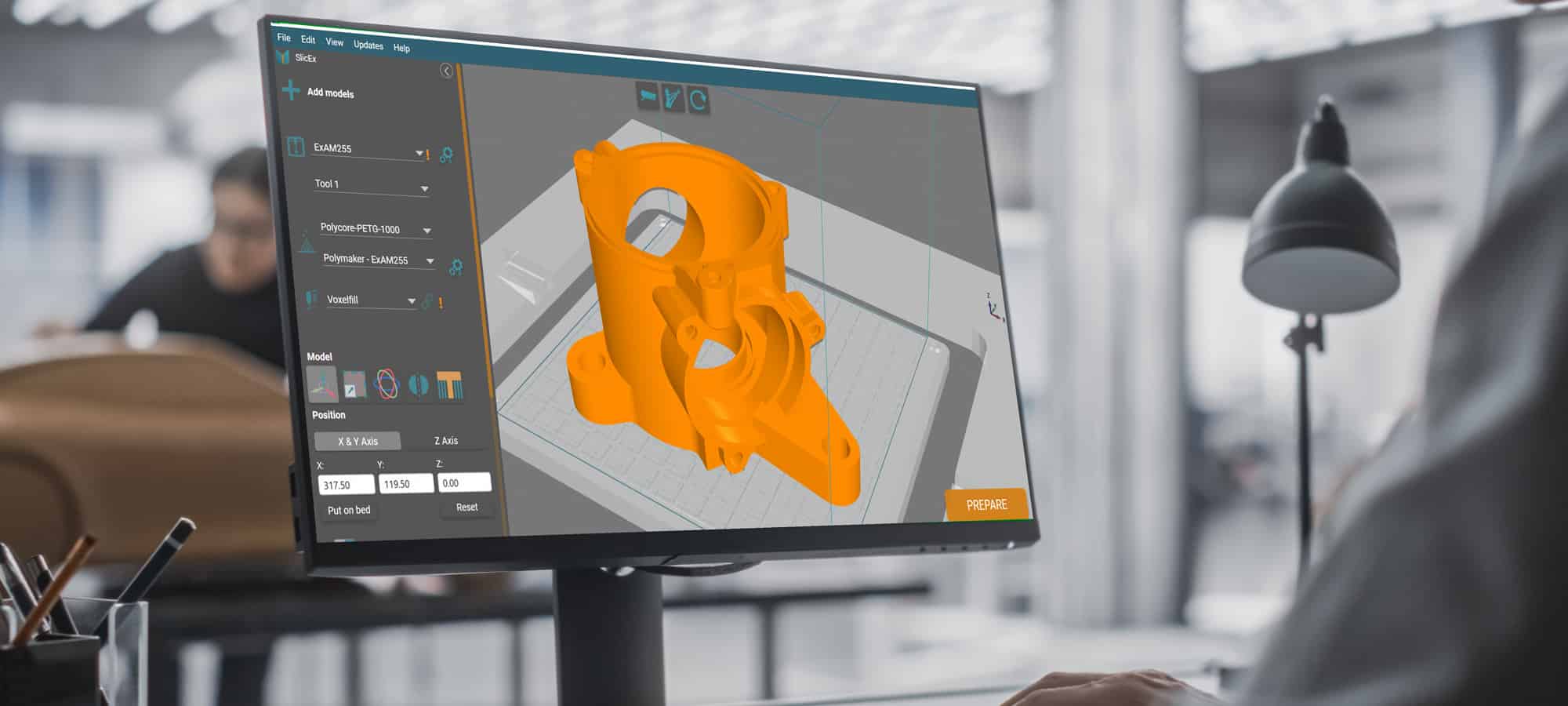

Strong 3D print strategies

We take the strength of printed parts to the next level

Voxelfill emerges as a game-changer by enhancing the strength and durability of 3D-printed objects. This patented 3D print strategy represents a paradigm shift in additive manufacturing technology, empowering creators and manufacturers to elevate cross-directional robustness and resilience in their parts. Voxelfill integrates seamlessly with various materials, including plastics, metals, and ceramics.

Ready for the next step?

Additive manufacturing is still young, but more and more businesses are becoming aware that traditional production methods need alternatives. As a business partner, we help you create the right setup for your 3D printing program. We can start with a consultation, or you can order a sample.