CUBIX - World's best custom insoles for diabetes

Recyclable, locally produced, and adaptable to any shoe. Innovative in-house 24/7 production for orthopaedic craftsmen and medical supply stores.

CUBIX 3D-printed inserts

The CUBIX system offers a flexible and modern solution for the supply of 3D-printed insoles. With the two printer models, CUBIX LITE and CUBIX PRO, both comfort and premium insoles can be produced directly in your own production environment. This results in efficient, clean, and economical 24/7 manufacturing, enabling high-quality, reproducible insole supply.

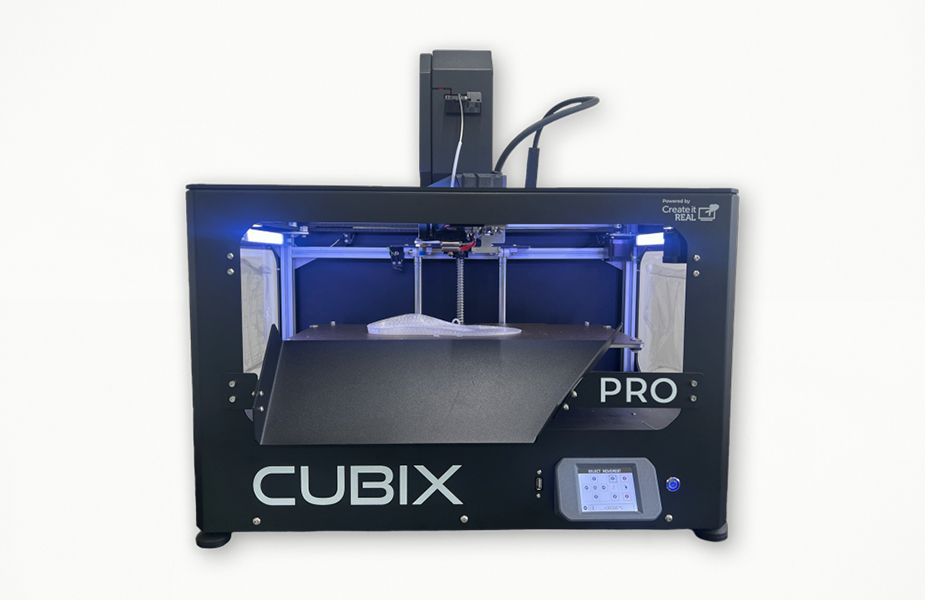

CUBIX PRO

Features:

- The premium insole for the highest demands.

- Optimally suited for: PG31 and PG08. Ideal for: diabetic care, beddings and feet with special needs.

- Seamless hardness adjustment in seven steps: Shore hardness from 20A to 79A.

- Precise zone adaptation: individually configurable.

- Print with toe spring and support structure.

- Printing time approximate 6 hours per pair. Output in 24 hours: 4 pairs.

- Continuous 24/7 production with Automatic Extraction.

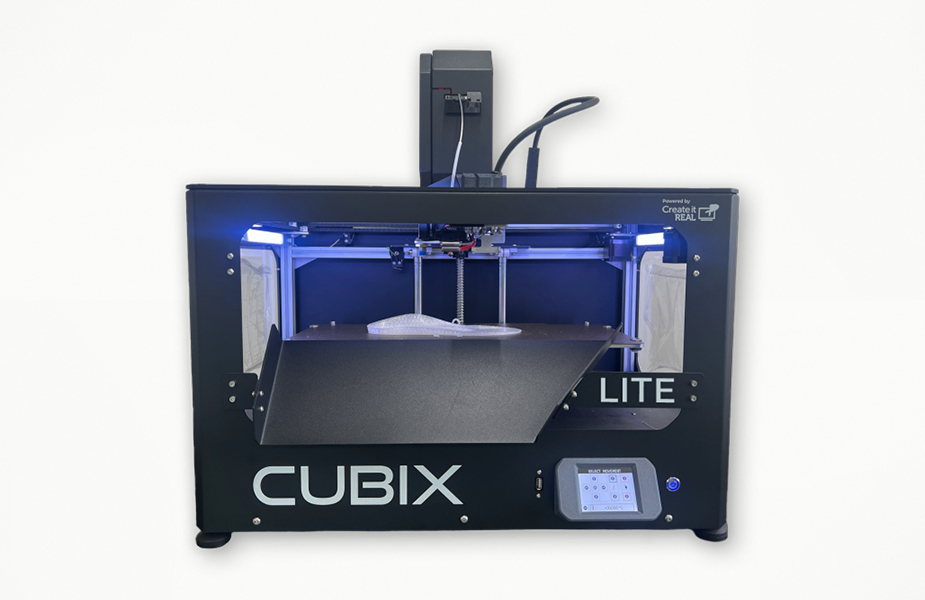

CUBIX LITE

Features:

- The perfect all-rounder in the mid-price segment. Individual adjustments, e.g. forefoot pad, metatarsal pad.

- Seamless hardness adjustment in three steps: Shore hardness from 30A to 60A.

- Fast printing times approximate 3 hours per pair. Output in 24 hours: 8 pairs.

- Continuous 24/7 production with Automatic Extraction.

Scanning - CAD - Preparation

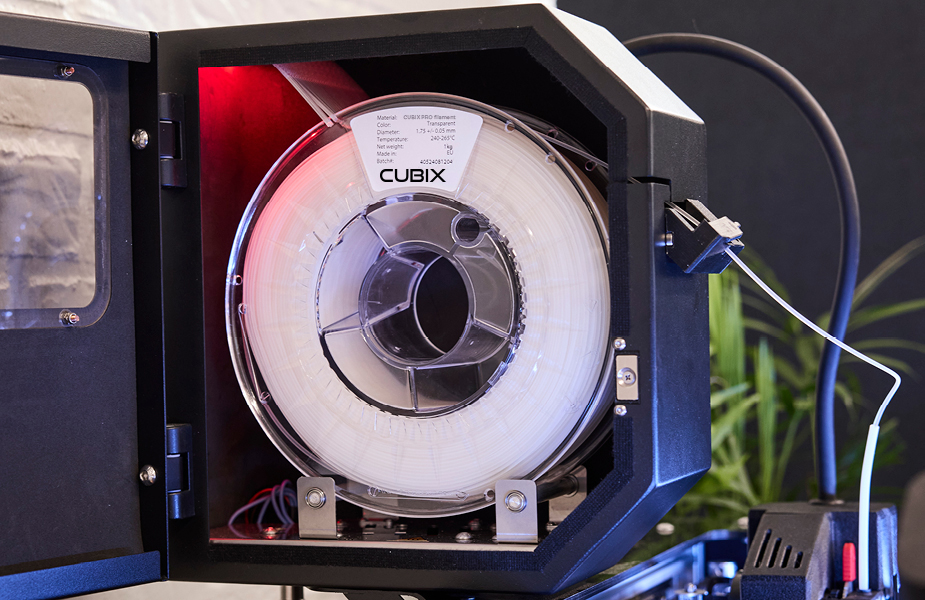

Printing material

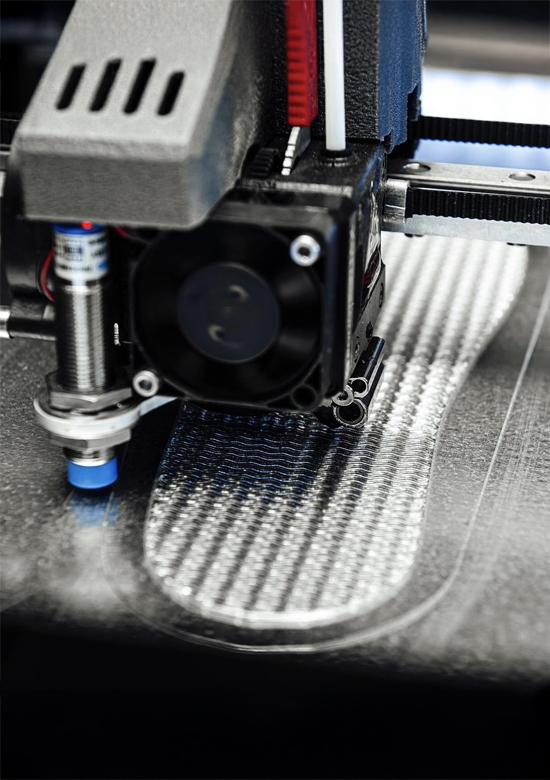

Programmable Foam® is our patented 3D-printed foam technology that replaces traditional molded foams in custom insole applications. It offers superior comfort, hygiene, and performance, engineered entirely from our specialized CUBIX Filament.

The material and structure of Programmable Foam® bring multiple advantages:

- Non-absorbing and washable: The foam does not retain moisture and can be safely washed in a standard washing machine at up to 60°C (140°F), making it easy to clean and maintain.

- Fire-retardant: Tested and compliant with EN 1021-1, EN 1021-2 fire safety standards.

- Biocompatible and skin-safe: The material has passed critical biocompatibility assessments: Cytotoxicity testing according to ISO 10993-5:2009 and in vitro sensitization following ISO 10993-10:2021

These validations confirm the foam’s safety for prolonged skin contact and use in health-related applications.

From a sustainability standpoint, 3D printing with CUBIX TPU generates virtually zero waste, and when paired with a TPU recycling scheme, significantly reduces the environmental impact compared to traditional foam manufacturing.

CUBIX Academy

At CUBIX, we’ve created a unique community specifically designed for our B2B customers. Here you’ll find regular training sessions, workshops, and user meetings to expand your knowledge and benefit from best practices.

Our Discord server offers you the opportunity to connect with like-minded individuals in real time, ask questions, and share ideas.

The CUBIX Marketing Cloud is available to provide you with instant access to the latest information and resources.

Recycling and waste

Recyclable materials. Virtually zero waste.

Our insoles are engineered to reduce environmental impact from start to finish—combining responsible materials with a highly efficient manufacturing process that leaves almost nothing behind.

Get a quote

Master High-Volume Production with a CUBIX Print Farm

Insoles

Master High-Volume Production with a CUBIX Print Farm

A fully integrated, scalable 3D printing solution for insole manufacturing, built for continuous production. From insole design to print management, everything is connected in one seamless workflow. Deliver consistently high-quality insoles while scaling effortlessly—from a single printer to a fully integrated production fleet. Start small, expand with confidence, and increase output without disruption or hidden costs.

The recycling loop

Integration into your CAD software makes it possible to prepare the print and add the insole to the print management system in one go, using a cloud-based version of the REALvision software engine.

How to get started with 3D printed insoles

We are prepared to assist you in implementing a digitalized workflow and starting production through 3D printing.

- Define your business case.

- Create samples.

- Determine a suitable solution.

- Control and initiate production.

- Scale production.