Joann needs to increase the time with patients

Joann is a 42-year-old fictional orthopedic specialist who works at a clinic that offers custom orthopedic products. Today, handcrafting is a big part of her work. She is used to sculpting solutions. It can be a corrective brace for an adolescent in a scoliosis treatment program, a molded seat for special support needs, custom insoles with different hardness zones, or even a cushion with zones. In general, all these products are handcrafted today, and the issue is that Joann wants to free up time to see more patients.

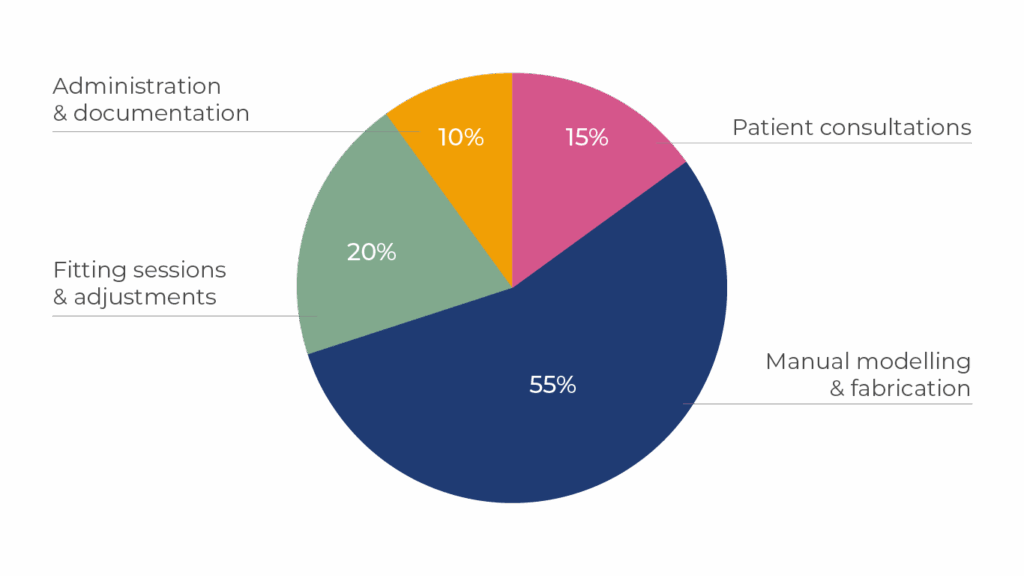

Let’s look at how her time is spent today.

How Joann's time is spent today - handcrafted workflow

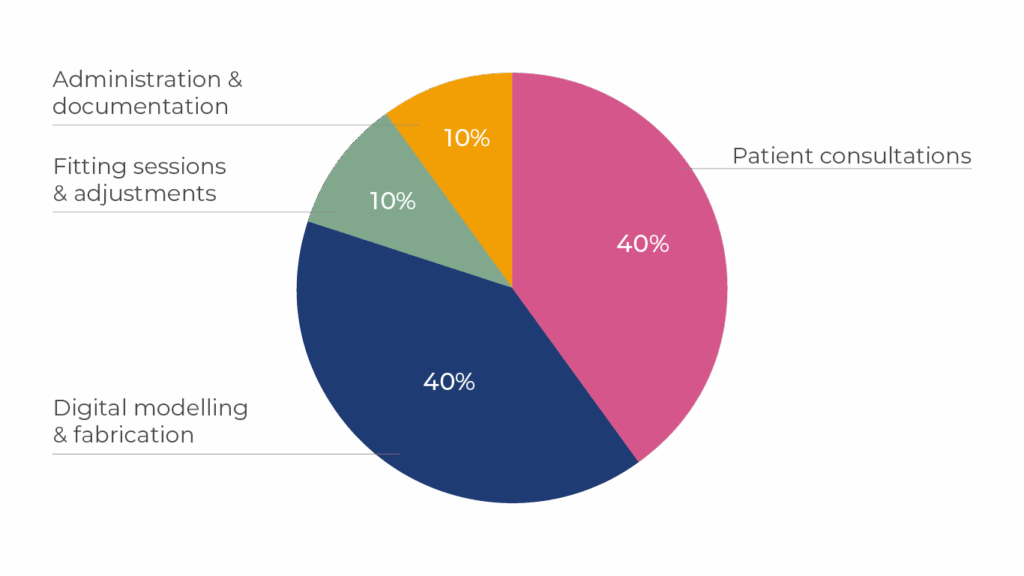

What will happen if she changes to a digital workflow?

Joann is worried about the future because she feels the pressure. She sees her colleagues aging, and the younger generation is not that eager to learn the craftsmanship. The new generation is much more digital. She also sees the numbers of an aging population and worries if she can keep up when recruitment is difficult.

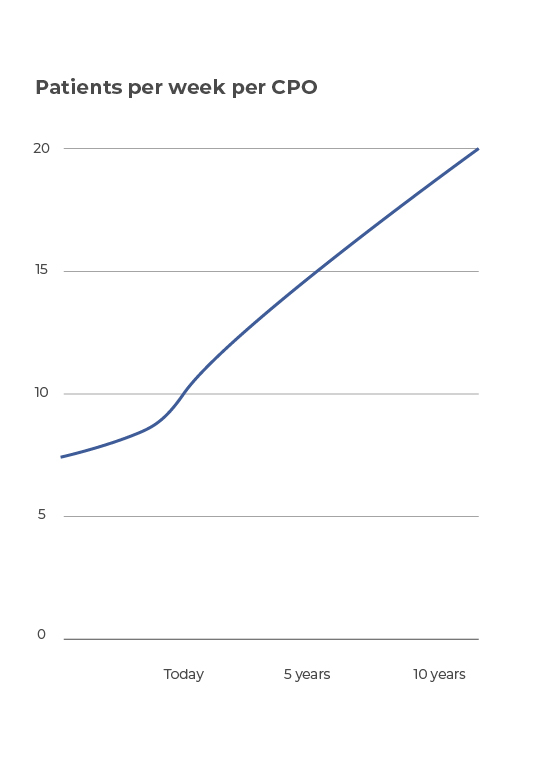

She learned that a study found 109 vacancies in the UK P&O workforce, and that 43% of NHS trusts and 57% of private companies reported being unable to recruit for those posts. So already now she has to run faster, but what happens when we look at the future needs? In this graph, we examine how many patients Joan will need to see in the future.

Interpretation:

- Under conservative growth (+30% over 5 years), clinics must increase technician throughput by roughly 30% from today to keep up if headcount remains constant.

- Under the 10-year conservative growth (+60%), the required productivity increase is around 60%.

- These increases are materially smaller than the earlier doubling assumption, but still substantial and not achievable without workflow changes if recruitment remains difficult.

Sources to justify the growth assumptions and workforce limits: WHO/AT needs and UK workforce mapping, plus EU employment trends for health professions.

So Joann needs to increase her productivity by 60% in 10 years.

She is already running so fast, yet the patients are still facing long wait times. Let’s look at the digital workflow. Even though it is hard for Joann to change the workflow right now, she doesn’t have the time to do it.

The future with AI-assisted design and automated production

- AI modelling tools reduce modelling time from 20–40 minutes to 3–8 minutes.

- Automated slicing strategies optimize strength without manual tuning.

- Production planning algorithms automatically balance machine scheduling.

- Digital workflows today cut time by up to 60%.

- With AI additions, clinics can move toward a 70–80% reduction in human labour per device over the next decade.

| Workflow state | CPO time required per patient* | Patients per week | Capacity change |

|---|---|---|---|

| Today | 2–4.5 hours | 10–12 | Baseline |

| Digital (today) | 1–2.5 hours | 14–18 | +40–60% |

| Digital 5 years | 0.8–1.5 hours | 18–25 | +80–120% |

| Digital 10 years | 0.4–1 hour | 25-35 | 2.5–3x |

*CPO time includes all tasks that require direct clinician involvement: patient consultation, data collection, digital or manual modelling, slicing, hands-on production steps, adjustments, and fitting.

References

- Brouwers L. et al. (2021). Comparison of conventional vs 3D-printed hand orthoses. Journal of Rehabilitation and Assistive Technologies Engineering.

- Brouwers L. et al. (2024). Feasibility of 3D-printed orthoses in hand therapy. Clinical Rehabilitation.

- Hsu C-Y. et al. (2024). Comparing remanufacturing and outcomes of 3D-printed vs traditional orthoses. Prosthetics and Orthotics International.

- Vertex Orthopedic (2025). Scan-to-delivery efficiency in orthotic 3D printing workflows.

- Salmi M. (2021). Additive manufacturing in medical devices: efficiency and applications.