Sport Klamser relies on 3D printing for customized insoles

Precision, speed, and sustainability with CUBIX technology

A faster, more precise, and sustainable method for producing custom insoles was achieved by transitioning from traditional crafting to a fully digital workflow.

Sport Klamser, based in Blaustein, Germany, has modernized its custom insole production with the CUBIX solution, which includes everything required to produce high-quality 3D-printed insoles within a fully digital workflow. It enables the team to design and print customized insoles directly on-site — combining precision, speed, and sustainability.

One of the advantages of custom insoles is that left and right insoles can differ to match individual biomechanics, providing the highest level of customization while remaining efficient in production. Additionally, the system supports a circular economy, as used insoles can be returned and recycled through a deposit system — keeping materials in a closed loop.

“With CUBIX printing technology, we have revolutionized our workflow. Our customers now receive perfectly fitting insoles much faster, and we can focus even more on personalized service and consultation.”

— René Juen, CAD designer at Sport Klamser

Meeting rising customer expectations

Behind Sport Klamser is the ambitious Klamser family, deeply involved in running the business. For many years, Sport Klamser has been known for its expertise in sports equipment, footwear, and footcare solutions.

As demand for personalized insoles increased, traditional production methods could no longer keep pace. The process was time-consuming, required multiple appointments, and relied heavily on manual labor. It was also wasteful, and the working conditions were dusty and unappealing.

Sport Klamser has always been a frontrunner in innovation, so adopting a digital footcare workflow was a natural step. At the same time, customers were expecting faster delivery and individualized comfort, without compromising quality. The team wanted a solution that could meet these expectations — and the CUBIX solution delivered.

The CUBIX solution

CUBIX is a complete manufacturing system for producing custom insoles using additive manufacturing.

The solution includes everything needed to scan the foot, design the insole, define harder and softer zones, and produce it using certified printing materials and a specialized 3D printer.

An integrated academy program supports onboarding for professionals in custom footcare, covering both the technology and basic troubleshooting.

No prior 3D printing knowledge is required — only experience in analyzing foot needs and providing personalized comfort solutions.

For Sport Klamser, CUBIX was the perfect fit. It allowed them to leverage decades of experience in sports and comfort insoles while strengthening their position as a technology leader offering high-end, customized footcare products.

From CAD design to 3D-printed precision

When René Juen starts a new project, the first step is to create a digital model of the customer’s feet. This begins with a precise 3D scan that captures the exact shape and pressure points, which are then imported into CAD software.

Using this data, he models the insole to match the wearer’s individual anatomy and needs.

The technology allows the addition of zones with varying hardness or softness, using patented gradient transitions that ensure a natural feel under the foot.

Because feet are highly sensitive, these transitions are essential to achieve the right balance between comfort, relief, and pressure distribution.

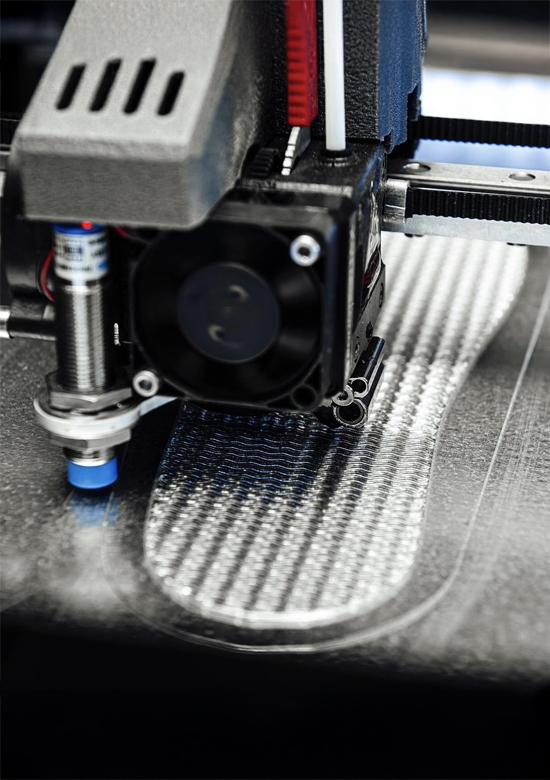

Once the model is finalized, it is transferred to the CUBIX 3D printer for printing.

Unlike standard 3D printers, producing soft insoles is a complex process: the certified TPU material requires extremely precise control to achieve consistent softness and quality from one insole to the next. Nothing less than a flawless, high-quality result is accepted.

This process enables Sport Klamser to manufacture custom insoles locally, providing customers with a faster and more sustainable solution — while freeing up time for personalized consultation and service.

Efficiency and sustainability in one workflow

Since adopting the CUBIX solution, Sport Klamser has achieved:

- Reduced manual labor by up to 50%, freeing time for consultation.

- Shortened turnaround and adjustment times, delighting customers.

- Produced insoles with precise biomechanical performance, ensuring comfort and control.

- Minimized waste and embraced material circularity, thanks to TPU’s recyclability and the deposit-based recycling system.

A model for the future of digital footcare

By combining advanced 3D printing technology with professional expertise, Sport Klamser has set a new standard in digital footcare.

With CUBIX, they’ve shown that the future of custom insole production lies in digital precision, local manufacturing, and a circular approach to materials — delivering better results for both customers and the planet.

The partnership between GeBioM and Create it REAL combines over 30 years of experience in foot health innovation with the energy of a young technology pioneer.

It’s the story of a successful disruption — built on deep field experience and cutting-edge technological expertise. It’s also a collaboration between a company on its sustainability journey and a partner born green with additive manufacturing.