Programmable Foam® technology – when your life depends on it

Support isn’t just about shape—it’s about protecting comfort, hygiene, and health. Programmable Foam® helps you design safer, cleaner, and more consistent products for people who rely on them every day.

Key benefits

Go digital

Hygienic foam

Pressure distribution

- Accurate, supportive positioning:

Create cushions and seats that provide targeted relief with softer and harder zones to match individual needs.

- Lasting comfort with fewer adjustments:

The durable structure maintains its shape and performance over time, reducing the need for replacements or refittings.

- Replicable and adaptable:

Do you need a replacement or an updated version? Reprint or modify the original digital design easily and quickly. - Ventilation and microclimate:

Promote skin health and comfort by improving airflow, reducing heat buildup, moisture, and odor. - Minimal waste:

The digital additive manufacturing process produces only what’s needed, generating up to 99% less material waste than traditional foam shaping. - Sustainable by design:

Supports UN Sustainable Development Goals by reducing waste, using energy-efficient additive manufacturing, and enabling longer-lasting products. - Customize to fit:

Design custom seating, cushions, and insoles that address individual needs, such as pressure relief, shock absorption, and hygiene. - Shock absorbing:

Reduces strain on joints and spine, improving comfort for active users or those in prolonged seated positions.

More than foam. A tested, certified, digital alternative

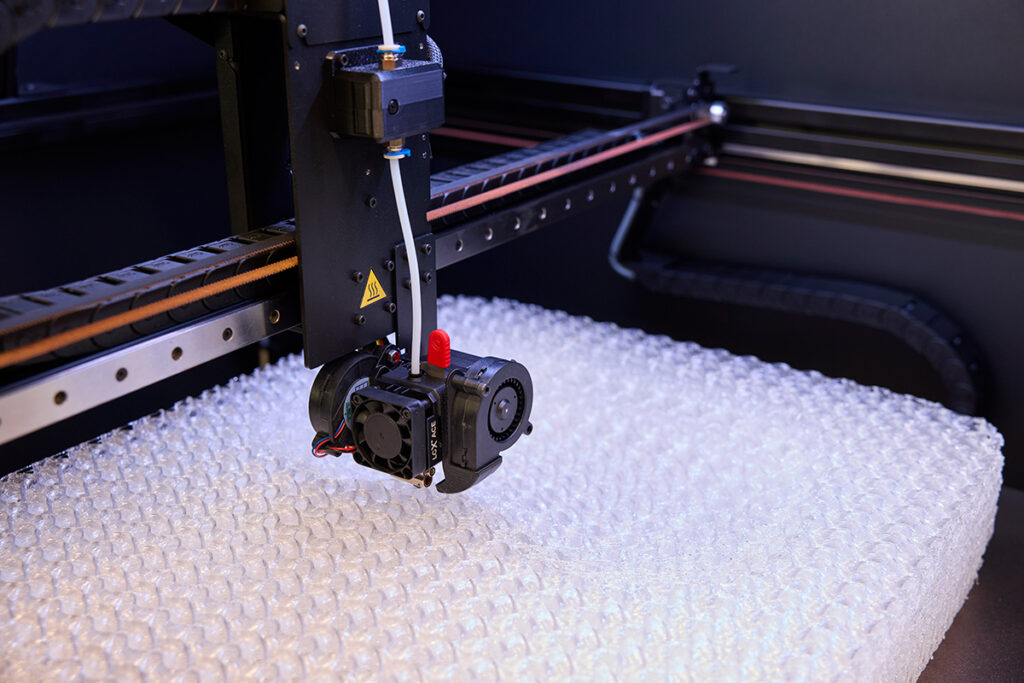

Programmable Foam® replaces traditional molding and manual shaping with a fully digital process. Every print is tailored, repeatable, and documented, reducing human error and enabling traceable, patient-specific care.

In-house safety and durability tests

Built to last, tested to prove it. Our in-house safety and durability program puts the material through rigorous washing and hygiene simulations to ensure it performs under repeated cleaning. Fire resistance trials, combined with load and compression testing, demonstrate resilience under pressure. And with long-term use cycles confirming reliability over time, you can trust it to deliver consistent performance in daily clinical practice.

When your life depends on

Custom devices enabled by additive manufacturing

When your life depends on wheelchair seating

Download our white paper and learn why microclimate is a critical and often underestimated factor in wheelchair seating. Based on clinical research, standardized testing, and real-life user experiences, the paper explains how heat, moisture, and airflow directly affect pressure injury risk, hygiene, and long-term health.

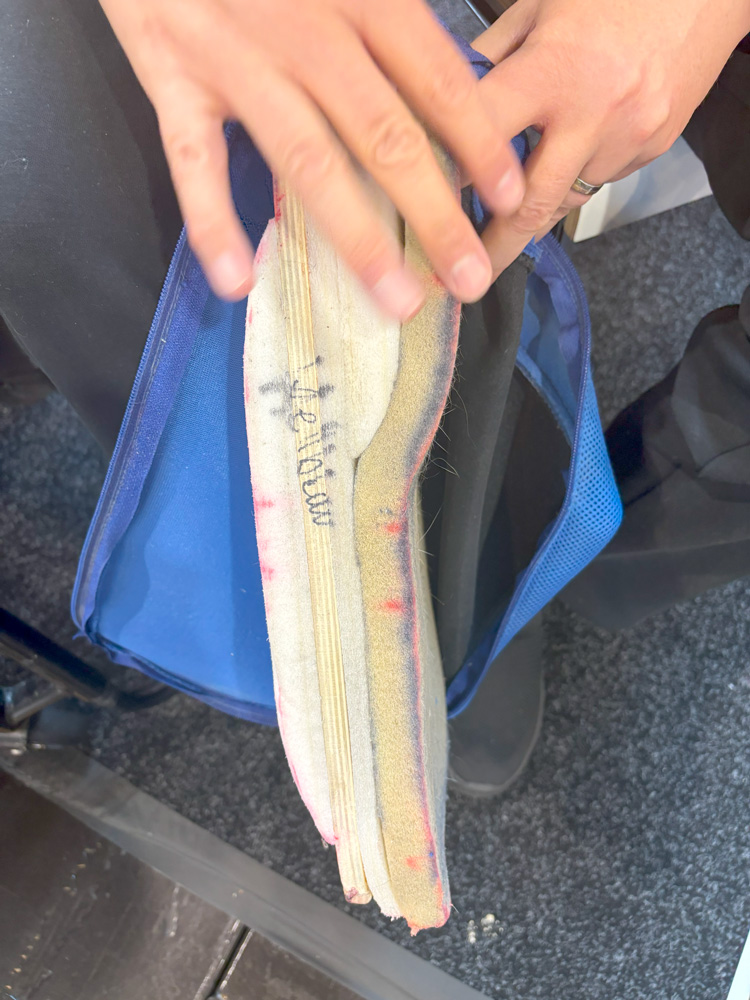

Imagine the possibilities

Programmable Foam® is ready to produce customized applications for various purposes, including insoles, seats, cushions, medical devices, and beyond. We are the technology partner enabling your ambitions and co-creating new innovative products based on your unique know-how and Programmable Foam®.

The patented foam technology sets new clinical standards

Support is more than shape — it’s safety, hygiene, and lasting comfort. Programmable Foam® brings precision, protection, and repeatability to every seat and insole you create.

Born from additive manufacturing and built for clinical use, Programmable Foam® replaces traditional foam with a certified, digital workflow. It enables zone-specific performance, smooth and cleanable surfaces, and tested durability — all in a single print. No carving. No layering. No waste.

Already in use in wheelchair seating, cushions, and insoles, Programmable Foam® is trusted by clinics and partners who design for real lives. We work with medical professionals, brands, and service providers to deliver both standard and fully customized solutions.

Tested in labs. Trusted in clinics.

Proven where it matters most. Independent validation and rigorous pressure mapping studies show how our technology consistently performs under clinical demands. Performance testing at leading institutions, including the University of Pittsburgh, further underscores its ability to deliver measurable outcomes. And with strong potential for infection control, it not only supports better comfort and safety but also helps clinicians provide a higher standard of care with confidence.

University of Pittsburgh

The University of Pittsburgh’s Wheelchair & Cushion Standards Group specializes in applying and translating national and international performance standards for wheelchair cushions into practical, actionable insights.

Leveraging standardized ISO 16840 testing protocols, their team has independently evaluated around 50 different wheelchair cushions across a diverse range of performance metrics—such as immersion, envelopment, impact damping, hysteresis, horizontal stiffness, stability, and pressure mapping—to help stakeholders make informed decisions based on objective data.

Our technology has also been tested by this group, and the results confirmed its performance according to these international standards.

Certified. Protected. Built for healthcare

At the core of our innovation is intelligent software that controls the entire process. Using our unique, multi-patented 3D printing methods, the software precisely adjusts volumetric density across different zones of a design. By modulating line width through smart speed control, we create smooth gradient transitions between softer and firmer areas—essential for targeted pressure relief and optimized performance.

Developed specifically for healthcare applications, the technology allows clinicians and designers to define material properties directly in the software, while the printer faithfully translates these digital instructions into reality. Backed by a strong portfolio of granted and pending patents worldwide, this seamless connection between software and hardware delivers a protected, proven foundation for advanced medical devices.

Programmable Foam® is more than a material—it’s a technology platform that secures your end product:

- ISO testing and documentation.

- Clinical use ready.

- Protected by multiple patents.

- Designed to comply with MDR/CE pathways.

We learned to live with foam’s flaws — but should we?

Foam has long been the go-to material for custom seating. It’s soft, easy to shape, and widely available. But it also absorbs fluids, breaks down over time, and often requires chemical treatment just to be safe enough. We’ve accepted those trade-offs because there was no better option.

Now there is.

Programmable Foam® outperforms traditional foam on the parameters that matter most, especially when your health, safety, and comfort depend on it.

| Traditional foam | Versus | Programmable Foam® |

|---|---|---|

| Absorbs moisture, hard to clean | Surface hygiene | Smooth, sealed surface – hygienic and easy to wipe |

| Often not washable or damaged by liquids | Washability | Fully washable – withstands cleaning and disinfection |

| May require additives for fire resistance or waterproofing | Chemical treatment | No chemical additives – safety by design |

| Poor ventilation – heat and moisture buildup | Micro-climate | Designed airflow and ventilation – cooler and drier |

| Limited ability to adapt to body zones | Pressure distribution | Zone-specific control for even, customized support |

| Breaks down over time, especially with use | Durability | Long-lasting, tested durability |

| Manual shaping leads to variation | Repeatability | Digitally controlled and fully repeatable |

| High waste from carving | Material waste | Minimal waste – printed to the final shape |

| Limited and inconsistent due to uniform density | Shock absorbing | Precisely tuned properties that absorb shocks and improve comfort and safety |

What our customers say

Sustainable breakthrough

Reduce waste in manufacturing

For people who depend on custom seating and orthotic solutions, comfort and safety are non-negotiable. At the same time, we live in a century where caring for the planet matters more than ever. Until now, these priorities have often been at odds with one another.

Programmable Foam® changes that. By combining advanced digital manufacturing with clinical-grade performance, we deliver solutions tailored to individual needs and designed to minimize environmental impact. Our process reduces material waste by up to 99% compared to traditional foam shaping — a breakthrough in sustainability for personal care products.

Sustainable development goals

The Programmable Foam® technology platform supports key UN Sustainable Development Goals:

- Good health and well-being (SDG 3): delivering safe, hygienic, and comfortable solutions for those who need them most.

- Responsible consumption and production (SDG 12): enabling precise manufacturing that avoids waste.

- Climate action (SDG 13): reducing carbon footprint across the product’s life.

Custom care has always been essential when lives are at stake. And when your life depends on a product designed just for you, it’s time that the product also reflects the world you want to live in. Now, for the first time, personal care and planet care come together — because caring for one should never mean compromising the other.