Wheelchair cushions

The Programmable Foam® wheelchair cushion enables you to offer anything from standard to customized orthopedic cushions. A high-end, hygienic alternative to traditional foam or gel—comfortable, sustainable, and washable.

Smarter seating, made possible by Programmable Foam®

Optimal pressure distribution

Better hygiene

Washable

Explore the advantages gained through a digital workflow:

- Fewer adjustments over time: Durable structure keeps its shape and function longer.

- Fire retardant: Safer than a seat produced from traditional foam. When exposed to open flames, it melts instead of burning.

- Replicable: It can be a true copy if you need a second seat. The digital file can easily be reprinted or adjusted.

- Micro-climate and ventilation: improve comfort, and prevent moist skin

- Minimal material waste: Our digital process eliminates foam offcuts, supporting your sustainability goals, up to 99% less waste than the traditional foam seat.

Designs that deliver

Discover how professionals are using our technology to solve complex seating challenges—delivering better outcomes for their users, with precision and confidence.

3D-printed cushion transforms Stephanie’s game

Stephanie Altmeier has played wheelchair basketball for over 20 years and recently started para-badminton as well. As an ambulatory wheelchair user with a genetic condition causing chronic pain and hypermobility, she always adapted to the challenges of her sports. But five years ago, her body started pushing back—hip and back pain made training difficult, and her standard foam cushion wasn’t giving her the support she needed.

At RehaCare 2024, Stephanie came across a potential game changer: a 3D-printed cushion in Programmable Foam® from Wolturnus, powered by the Create it REAL print service.

When your life depends on wheelchair seating

Download our white paper and learn why microclimate is a critical and often underestimated factor in wheelchair seating. Based on clinical research, standardized testing, and real-life user experiences, the paper explains how heat, moisture, and airflow directly affect pressure injury risk, hygiene, and long-term health.

Why switch to 3D printed cushions in Programmable Foam®?

Traditional foam seating—like foam seat cushions or padded wedges—has served wheelchair users for years. But for people spending long periods sitting, especially in manual wheelchairs, the risks of pressure sores, discomfort, and poor posture remain high. These cushions often absorb moisture, trap heat, and degrade with time, raising hygiene concerns and contributing to skin breakdown. Manual shaping is labor-intensive and inconsistent, often resulting in uneven support that compromises posture and pressure distribution.

Programmable Foam® offers a smarter way forward. It’s designed for businesses ready to modernize workflows and deliver a better seating experience through digital precision and patented technology. By enabling improved airflow and reducing heat and moisture buildup, it helps maintain a healthier micro-climate, crucial for preventing ulcers and supporting an active lifestyle in a wheelchair.

Create a better cushion today

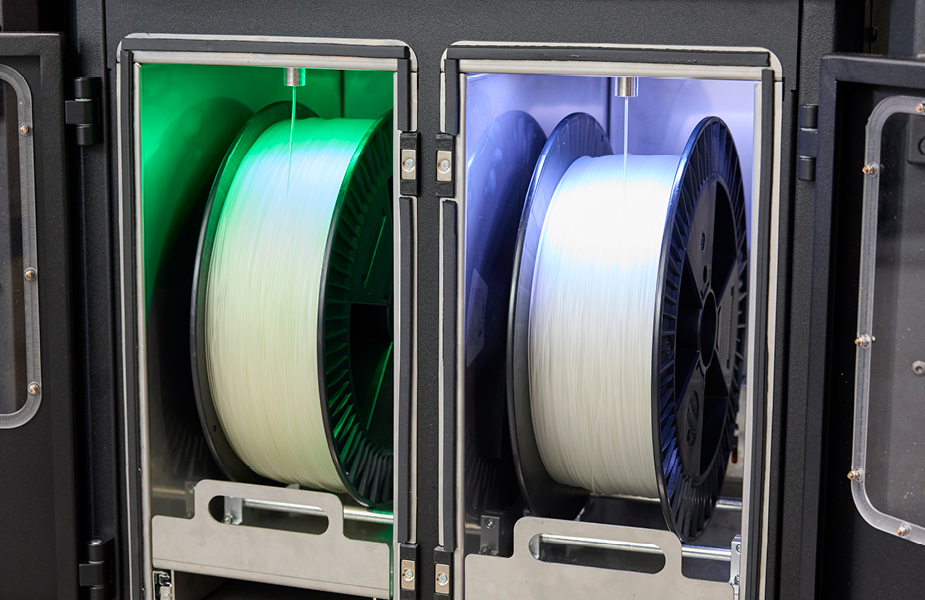

Print on demand or power your own production line

3D print service

Production solutions

Get a high-end cushion from Meyra

Netti Precision™ high-end seat cushions for wheelchairs

Meyra Group has developed the Netti Precision seat cushion range for users of comfort, active, and power wheelchairs. These cushions are designed to deliver outstanding seating performance with a focus on individual needs.

Built on Ergomise Technology™, the Netti Precision cushions combine the innovative potential of Programmable Foam® with decades of clinical seating expertise.

The result is a range of cushions that provide:

- Exceptional skin protection

- Pressure distribution

- Microclimate control

- Comfort

- Durability

- Hygiene

By choosing Netti Precision, you gain the advantages of cutting-edge material science paired with specialist knowledge in wheelchair seating. It’s a clear demonstration of how Programmable Foam® and expert seating design are shaping the future of wheelchair cushions.

How Programmable Foam® transforms seating

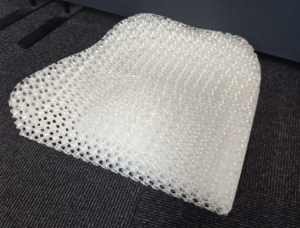

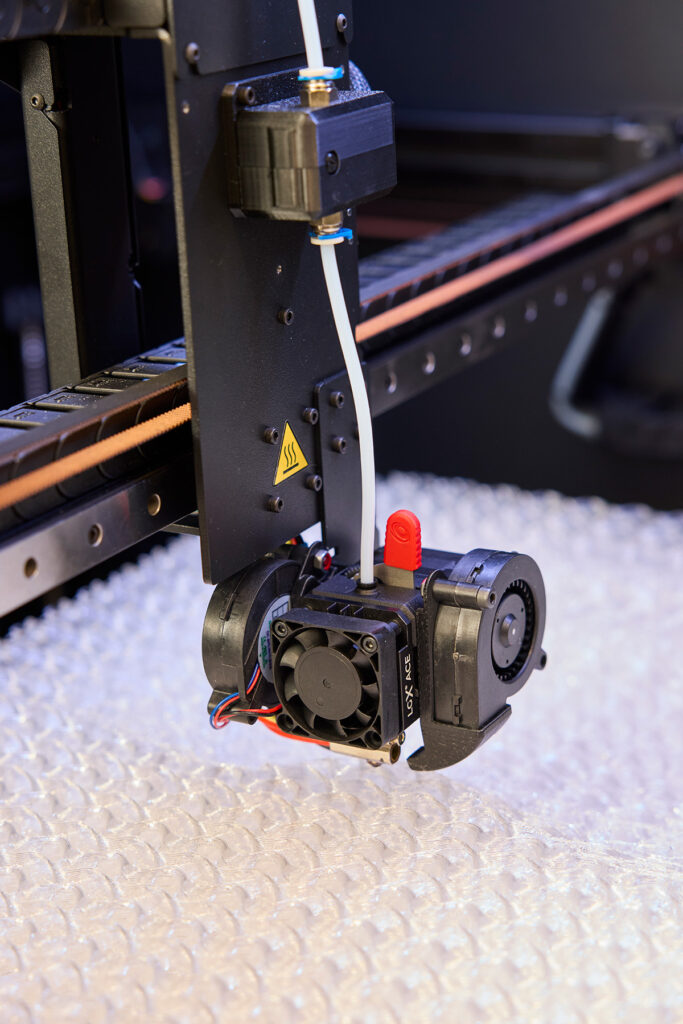

Programmable Foam® solution uses patented 3D printing technology to create contoured, customized seat cushions for wheelchair users. The digital process replaces manual cutting with a software-driven approach that improves precision, comfort, and consistency, without the material waste.

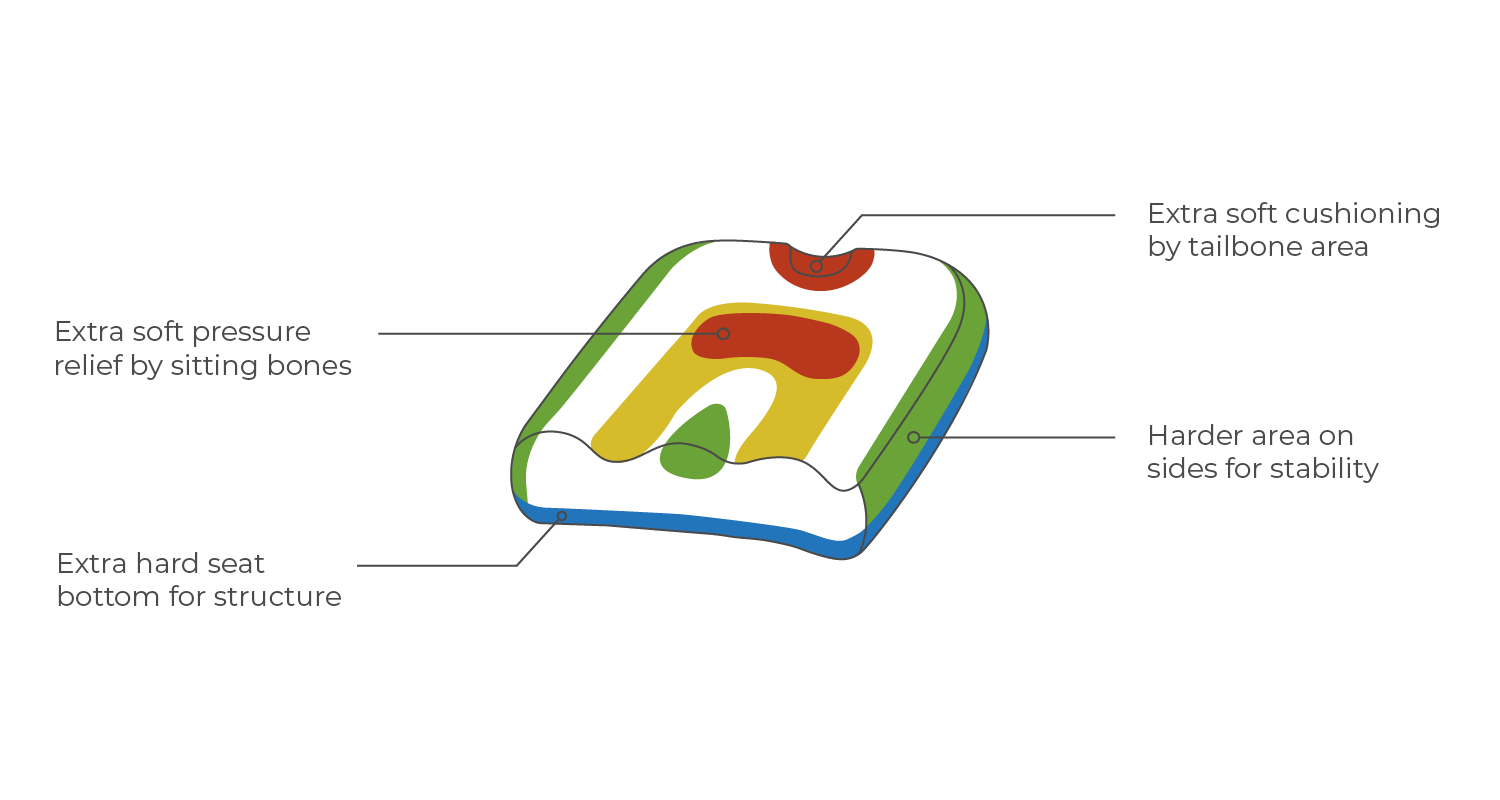

- Digitally designed: Each contoured cushion is modeled to support the coccyx, pelvis, and lumbar area, improving posture and minimizing pain.

- Additively manufactured: No cutting or carving—just pure additive layering using high-density, breathable polyurethane foam.

- Highly hygienic: The open structure allows for airflow and the non-absorbing material for easier cleaning. Cushion covers are washable and removable.

- Fewer pressure points: Strategic zoning and ergonomic shapes reduce the risk of pressure ulcers and improve comfort for long periods of sitting.

What you gain in the process

- A digital workflow that saves time and reduces manual labor.

- Greater customization, with consistent production quality.

- Eco-conscious production with minimal waste.

- Cushions that offer improved comfort, hygiene, and even pressure distribution.

- A patented, future-ready technology your customers can trust.

- Enhanced support for orthopedic needs like tailbone, coccyx, and lower back pain.

Cushion options for every seating need

- Seat cushions and foam seat pads for daily wheelchair use.

- Lumbar support cushions and backrests to reduce back pain and improve posture.

- Wedge cushions, cut-out cushions, and contoured pillows for pressure relief.

- Replace the gel foam hybrids and air cushions and obtain advanced pressure redistribution, featuring harder and softer zones.

- Each variation can be standard or custom-made.

Imagine what you can do for your clients

Programmable Foam® is ready to produce customized cushions. Get inspired and innovate what you could do for your clients.

Materials and hygiene

Every Programmable Foam® cushion is printed using high-density Thermoplastic Polyurethane that balances firmness and comfort. Our Programmable Foam® is:

- Non-absorbing, waterproof, and latex-free—ideal for users with sensitivities.

- Breathable and washable for easy cleaning and airflow.

- Compatible with washable cushion covers and incontinence protection.

- Resistant to bacteria, moisture, and odor buildup.

- More sustainable than traditional padding or upholstery foam.

Hygiene, airflow, and skin protection

- Made with breathable, non-absorbing TPU foam.

- Machine washable cushion and covers.

- Resistant to bacteria, incontinence issues, and odor buildup.

- Engineered to relieve pressure on bony prominences like the coccyx, sacrum, and pelvis.

From scans to seats—digitally

Digitalization is the biggest hurdle to getting the wheelchair seat that everybody deserves. A lot of professional knowledge is stored in manual processes and hard-earned experience. And getting started with a digital process is like turning everything upside down. We support your entire journey into digital manufacturing:

- Scanning and CAD tools to design the cushion.

- REALvision Pro software to control the process.

- 3D printers optimized for foam-based additive manufacturing.

Whether you’re building high-profile custom cushions or low-profile seat pads, our tools support various orthopedic applications, postural adjustments, and pressure relief strategies.

Let’s build your digital workflow

Ready to switch from traditional foam to a scalable, digital solution? Get in touch to learn how Programmable Foam® can reshape your workflow—and your seating offering.

To support a smooth transition, we’ve developed a proven system built around customer success. Whether you’re just starting out or scaling up, we’re here to guide you every step of the way.

What’s your biggest challenge? Chances are, we’ve seen it before. From our experienced business development managers to our dedicated customer success team, everyone is ready to support you with business case development, training, documentation, and ongoing assistance.

Frequently asked questions about 3D printed wheelchair cushions

What is a 3D-printed wheelchair cushion?

A 3D-printed wheelchair cushion is an orthopedic seating solution created using additive manufacturing. Unlike traditional foam cushions, it is digitally designed to match the user’s body shape and printed with customizable properties for comfort, hygiene, and pressure relief.

How is a 3D-printed cushion different from traditional foam?

Traditional foam cushions are shaped by cutting or molding a generic material. A 3D printed cushion is created from a body scan and printed layer by layer with programmable zones for shock absorption, ventilation, and support. This reduces pressure points, improves hygiene, and eliminates waste.

Who can benefit from a 3D-printed wheelchair cushion?

These cushions are ideal for:

- People at risk of pressure ulcers.

- Active wheelchair users who need better shock absorption.

- Users with complex seating needs or asymmetries.

- Those with incontinence concerns who need washable cushions.

Can this cushion help prevent pressure sores?

Yes. The cushion’s internal structure can be optimized to distribute pressure more evenly than traditional foam. This reduces the risk of pressure sores, especially over sensitive areas like the ischial tuberosities and tailbone.

How do you clean a 3D-printed wheelchair cushion?

The cushion is waterproof and washable. It can be rinsed or disinfected without absorbing moisture, making it far more hygienic than traditional foam or gel cushions.

What is Programmable Foam®?

Programmable Foam® is our patented 3D printed material structure. It allows us to vary softness, ventilation, and shock absorption throughout the cushion, tailored to the user’s anatomy and needs.

Is the cushion fire retardant?

Yes. The material used in our 3D printed cushions meets fire safety regulations for medical devices and wheelchair seating.

How long does a 3D-printed cushion last?

The lifespan varies depending on use, but our Programmable Foam® cushions are designed to maintain their shape and function longer than conventional foam. They resist sagging and moisture degradation.

Can I use this cushion with any wheelchair?

Yes. The cushion is made to fit your wheelchair model and dimensions. We work with professionals to ensure compatibility with your current setup.

How is the cushion made?

First, your seating specialist takes a 3D scan or digital impression. Then, we digitally design the cushion based on your body and seating requirements. It is printed, quality-checked, and shipped for final fitting.

Is this cushion reimbursable?

Depending on your country and insurance policy, it may be. We recommend checking with your local health authorities or insurance provider. We are compliant with the EU Medical Device Regulation (MDR).

Is this cushion suitable for children?

Yes. Our solution works for both adults and children. Pediatric cushions are fully customizable and can be updated as the child grows.

Who makes these cushions?

We manufacture the cushions using our patented Programmable Foam® technology. We collaborate with certified seating specialists and wheelchair manufacturers to deliver a complete, tailored solution.

Where can I get a 3D-printed cushion?

Talk to your orthopedic professional or wheelchair supplier. We work through approved partners and medical device specialists to ensure each cushion is properly designed and fitted.