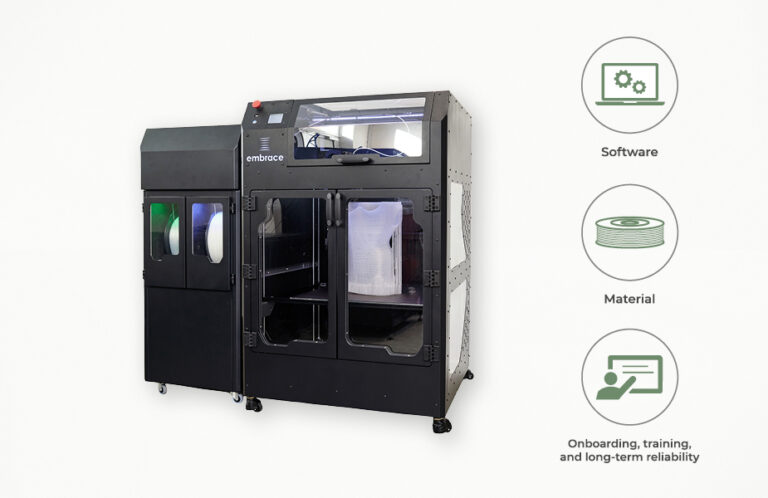

The Embrace corset solution

A dedicated manufacturing system for rigid spinal braces or soft body jackets using advanced 3D printing technology

Embrace corset solution - everything you need in a bundle

The Solution:

- Specifically designed for printing large-sized objects in rigid or softer material using polypropylene or thermoplastic polyurethane.

- Eliminates the need for extensive knowledge of printer specifications and materials.

- Reduces waste and post-processing, to save valuable time and effort.

CorsetMaker - Advanced 3D printer

- Optimized for flexible 3D printing using TPU and PP, specifically for applications like spinal braces and soft body jackets.

- Workspace dimensions: 60cm x 60cm x 65cm.

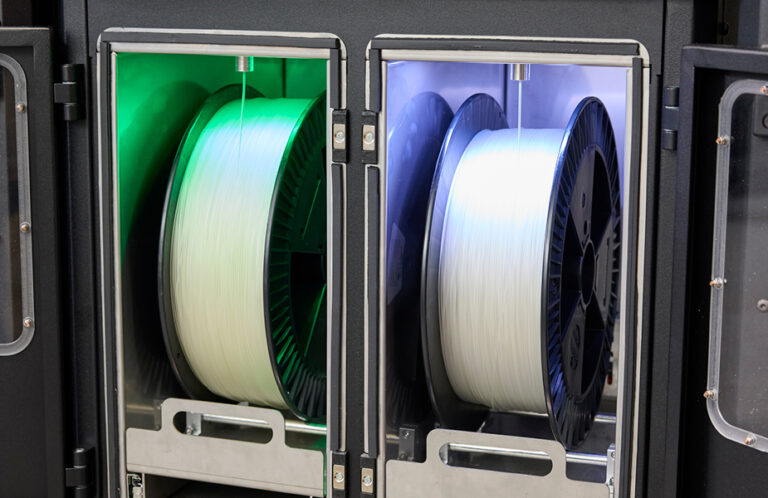

- Material properties: Certified and approved TPU and PP filaments.

- Automatic spool change for full utilisation and continuous printing.

- Automatic calibration.

- Power efficient – normal operation <150 W.

REALvision Embrace

A streamlined workflow from 3D model to printed product

REALvision Embrace CAM software supports a smooth, three-step workflow to produce personalized 3D-printed rigid spinal braces. It starts with preparing the 3D model and ends with a ready-to-print, customized design.

1. Prepare your 3D model

Start by preparing a 3D model in your CAD software that reflects the user’s anatomy and needs. This can be based on a 3D scan and an X-ray. This design file forms the foundation for targeted customization in the next steps.

2. Define soft and hard zones

With the 3D model ready as stl or obj, import the file into REALvision Embrace CAM to define precisely where soft and hard zones are needed. You can also add solid zones to mount straps.

Apply paintable surface-based modifiers with adjustable brush sizes or embed shape-based modifiers from the built-in library. An intuitive slider helps fine-tune each zone to optimize for optimal comfort and support.

3. Preview and print

Use the built-in visualization tools—like the modifier overlap view—to preview how the modifiers will be applied in the final print. You’ll also get accurate print time and material usage estimation, helping you plan and manage production efficiently.

Printing material

3D printing using specialized CREAtech TPU (thermoplastic polyurethane) and PP (polypropylene) materials.

Polypropylene

We use the same material as traditionally formed braces for rigid corrective spinal braces. With advanced 3D printing technology, it is possible to consider comfort in the design phase. Normally, a rigid brace has a uniform, inflexible thickness. However, with 3D printing, we can introduce flexible zones to prioritize comfort and more rigid zones in areas that require therapeutic support.

The innovation lies in the structure—the material remains the same throughout.

The material and structure bring multiple advantages:

- Lightweight alternative to traditional PP braces.

- Free from harmful substances: RoHS III compliant and free from Bisphenol A (4,4′-isopropylidenediphenol).

From a sustainability standpoint, 3D printing with CREAtech PP generates less waste. When paired with a recycling scheme, it significantly reduces environmental impact compared to traditional foam manufacturing.

The clean, dust-free additive manufacturing process makes it possible to produce seats and cushions in standard office or workshop environments, without the need for special ventilation systems.

Flexible thermoplastic polyurethane

For soft body jackets, we use flexible CREAtech TPU. These jackets are not part of an active treatment but serve as permanent corsets to prevent the condition from worsening.

The material and structure bring multiple advantages:

- Free from harmful substances: RoHS III compliant and free from Bisphenol A (4,4′-isopropylidenediphenol).

- From a sustainability standpoint, 3D printing with CREAtech TPU generates less waste. When combined with a recycling scheme, it significantly reduces the environmental impact compared to traditional foam manufacturing.

- The clean, dust-free additive manufacturing process allows for the production of seats and cushions in standard office or workshop environments, without the need for special ventilation systems.

Onboarding, training, and long-term reliability

Getting started with 3D printing can feel like a big step—but our dedicated customer success team ensures that it’s a smooth one. From the moment your Embrace solution arrives, we’re by your side to help you set up, learn, and grow with the technology.

Step-by-step onboarding

We guide you through the setup of both hardware and software, so you’re ready to begin production from day one. Every stage is designed to be straightforward, with clear instructions and personal support to make the transition easy and efficient.

Training and knowledge sharing

To help you get the most out of your Embrace solution, we provide comprehensive user guides, video tutorials, and tailored training sessions. As new features and improvements are released, we make sure you’re always up to date—so your workflow keeps improving with time.

Ongoing customer support

We’re here whenever you need us. Whether it’s answering questions, troubleshooting an issue, or offering advice, our team works closely with both you and our engineers to support reliable, high-quality production.

Logistics and material management

We take care of order processing for printers, materials, and spare parts—keeping your inventory stocked and your delivery schedule clear. You always know what to expect, and when.

Creative and technical services

From functional print files to label and sticker designs, we support both the technical and visual aspects of your products. We also offer print services where needed—delivering parts with precision and attention to detail.

Built-in maintenance and spare parts

To maintain consistent print quality, our service model includes the proactive shipment of critical spare parts. Each year, we send essential wear-and-tear components to keep your printer running at its best.

If additional parts are needed—due to damage or unexpected wear—they’re always available for quick delivery, helping you avoid unnecessary downtime.

Get a quote

Produce soft body jackets and rigid spinal braces with this solution

Rigid spinal braces

Soft body jackets

Integrate with your CAD system

Upgrade to mass production without missing the advantages of a simple and sustainable solution.

Integration into your CAD software makes it possible to prepare the print and add the insole to the print management system in one go, using a cloud-based version of the REALvision software engine.

With several printers connected, you can have a central print farm or manage several printers in local store locations, creating a decentralized print farm.

How to get started with 3D printed spinal braces and body jackets?

We are prepared to assist you in implementing a digitalized workflow and starting production through 3D printing.

- Define your business case.

- Create samples.

- Determine a suitable solution.

- Control and initiate production.

- Scale production.