Change your industry forever

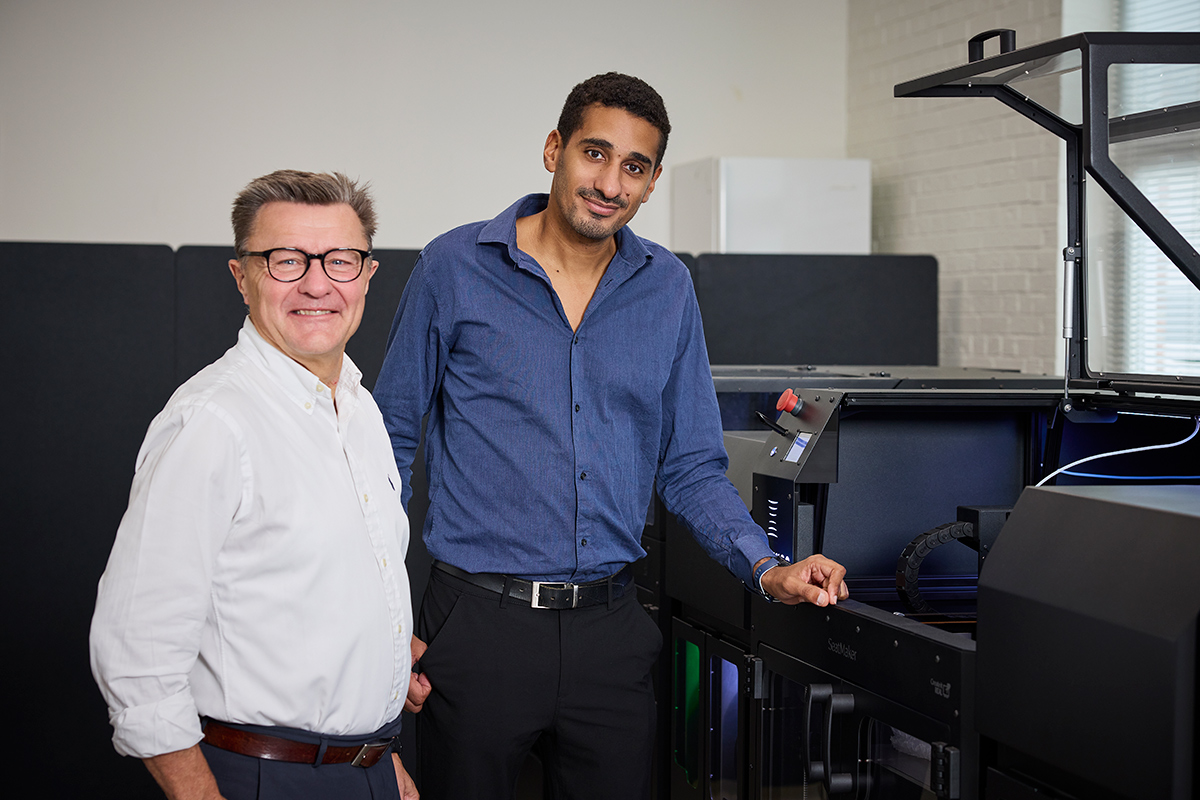

You bring the expertise. We bring the complete manufacturing solution. Our bundled solution makes it easy to produce high-quality orthopedic devices and fully harness the benefits of 3D printing—together, we push the boundaries of what’s possible.

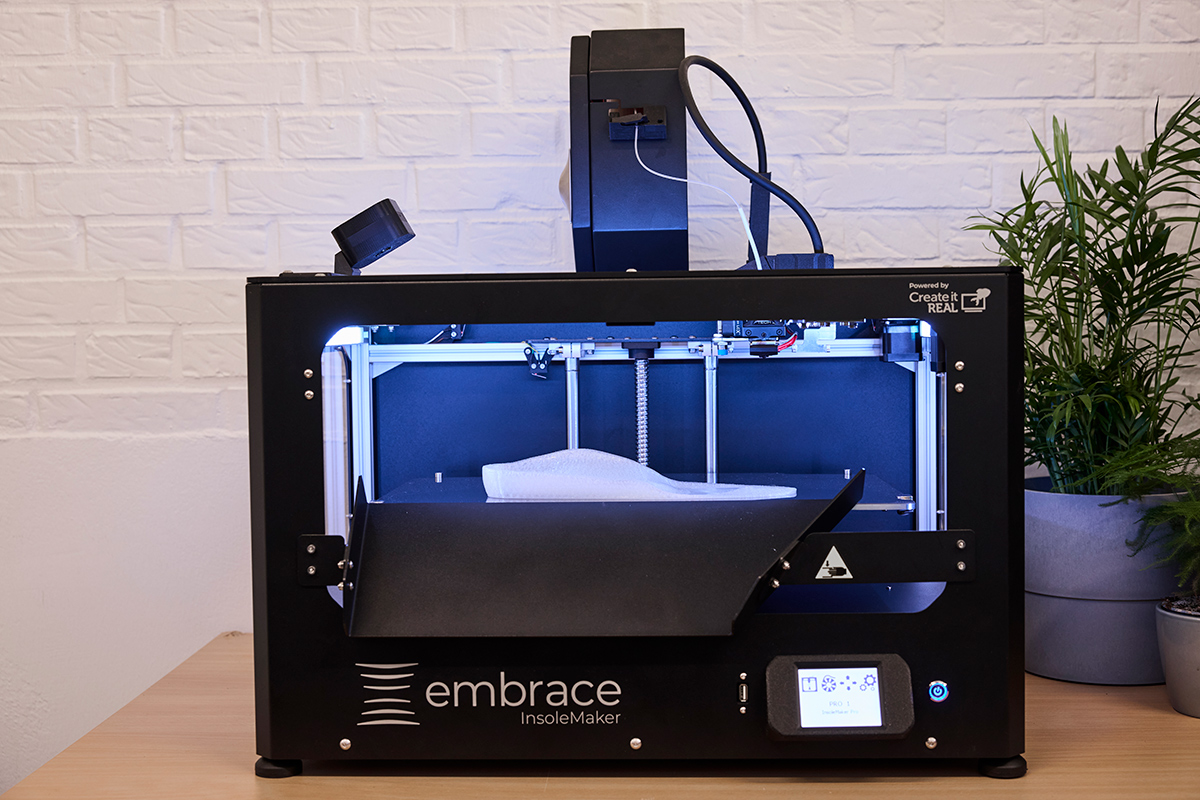

Embrace suite: Off-the-shelf manufacturing systems

Sustainability

Simplicity

Scalability

Everything you need to manufacture high-quality orthopedic devices

Our end-to-end manufacturing solution combines our 3D printer, proprietary software, and certified materials—all developed, tested, and optimized to work together as one powerful system.

This integration ensures consistent, high-quality results from the first print to full-scale production.

With a setup built specifically for orthopedic manufacturing, you can innovate, meet patient needs with precision, and reduce waste by up to 99% compared to traditional methods.

It’s how you move from complexity to clarity—and from concept to device with confidence.

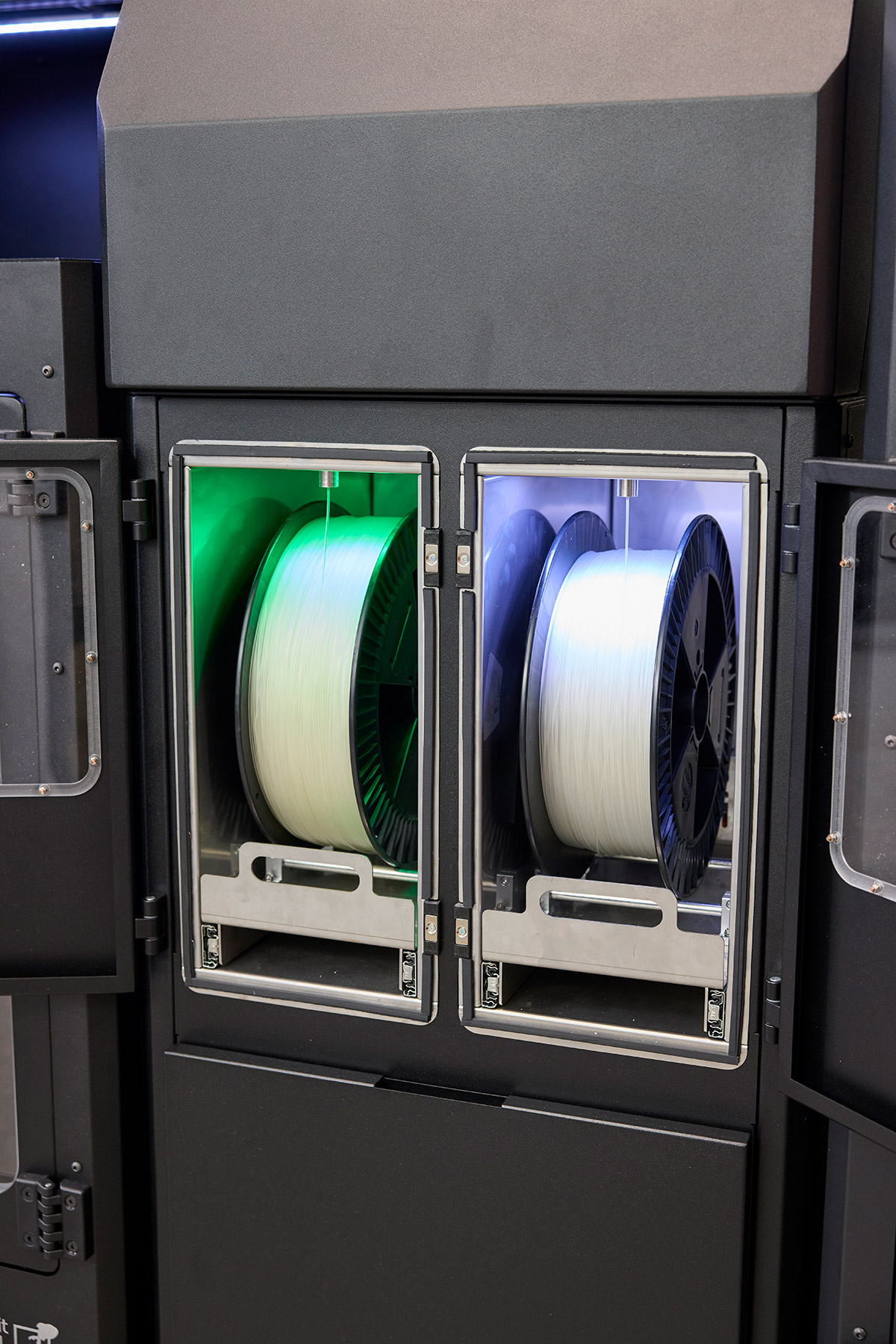

Certified material

Our material is specifically developed and customized for orthopedic applications—designed to optimize performance, print time, and the quality of the end product. Each formulation is tested to ensure it meets the demands of both the manufacturing process and the daily use of the device. There are no compromises: you get fast, reliable production without sacrificing comfort, durability, or safety for the end user.

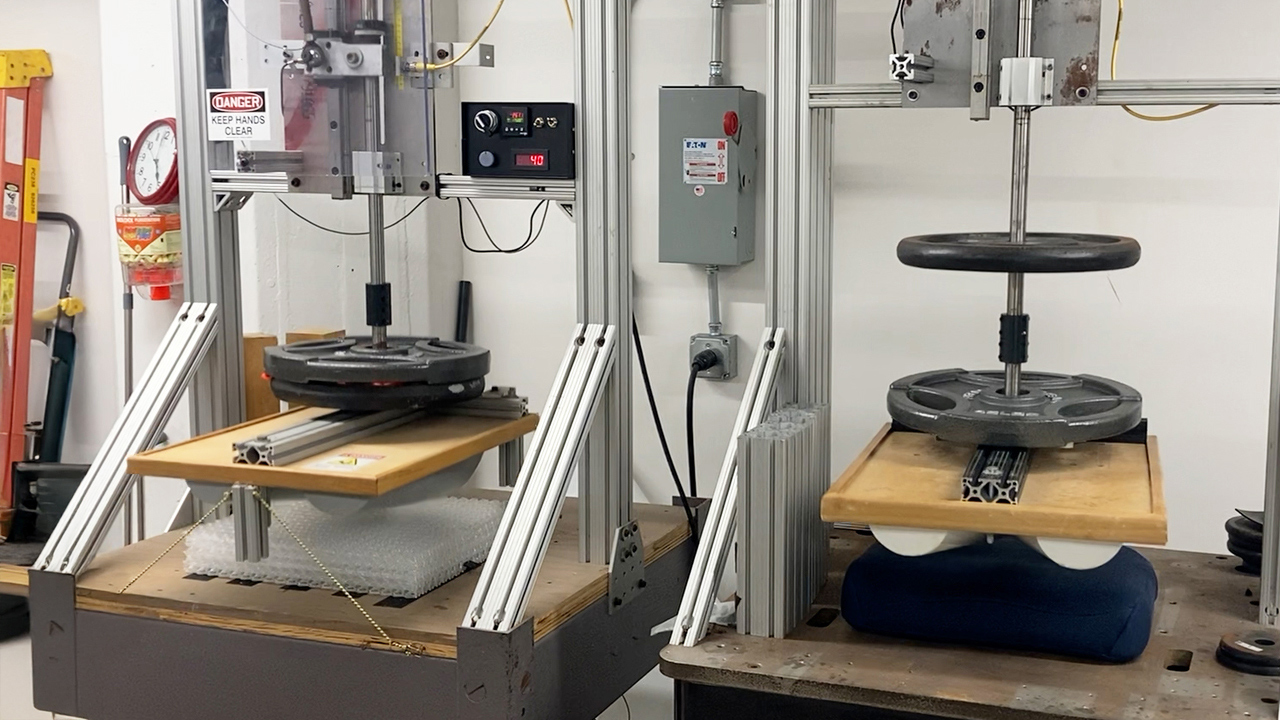

Tested technology

We collaborate with recognized institutions such as the University of Pittsburgh to rigorously test and validate our materials and manufacturing processes as part of our commitment to quality and reliability. This ensures that every component of our solution—from raw material to finished device—meets the highest standards for safety, durability, and clinical performance. In addition to in-house testing, our materials and end products undergo third-party certification to give you full confidence in their compliance and real-world usability.

A smooth start—and long-term support

Adopting 3D printing is a significant step—but with Embrace, it’s a structured, supported transition. From day one, our dedicated customer success team ensures you’re fully equipped to get started and grow with confidence.

Expect a guided onboarding, covering both hardware and software setup, so you can begin production without delay. Comprehensive training, clear documentation, and tailored resources help your team manufacturing high-quality products.

What sets us apart is our responsive support—real people ready to assist with technical questions, troubleshooting, or operational advice. We work closely with you to maintain reliability in your daily production.

It is also the customer success team who handles logistics, material supply, and spare part management, ensuring smooth operations with minimal downtime.

With an Embrace solution, you gain more than a manufacturing solution—you gain a trusted partner committed to your long-term success and a partner to grow together.

How to get started

We are prepared to assist you in implementing a digitalized workflow and starting production through 3D printing.

- Define your business case.

- Create samples.

- Determine a suitable solution.

- Control and initiate production.

- Scale production.