Custom orthopedic devices

3D printing takes medical devices to the next level—delivering both high quality and more responsible use of resources. Additive manufacturing enables precise customization and efficient production tailored to each patient.

Custom devices enabled by additive manufacturing

Mass customization

Comfort and support

Optimal use of resources

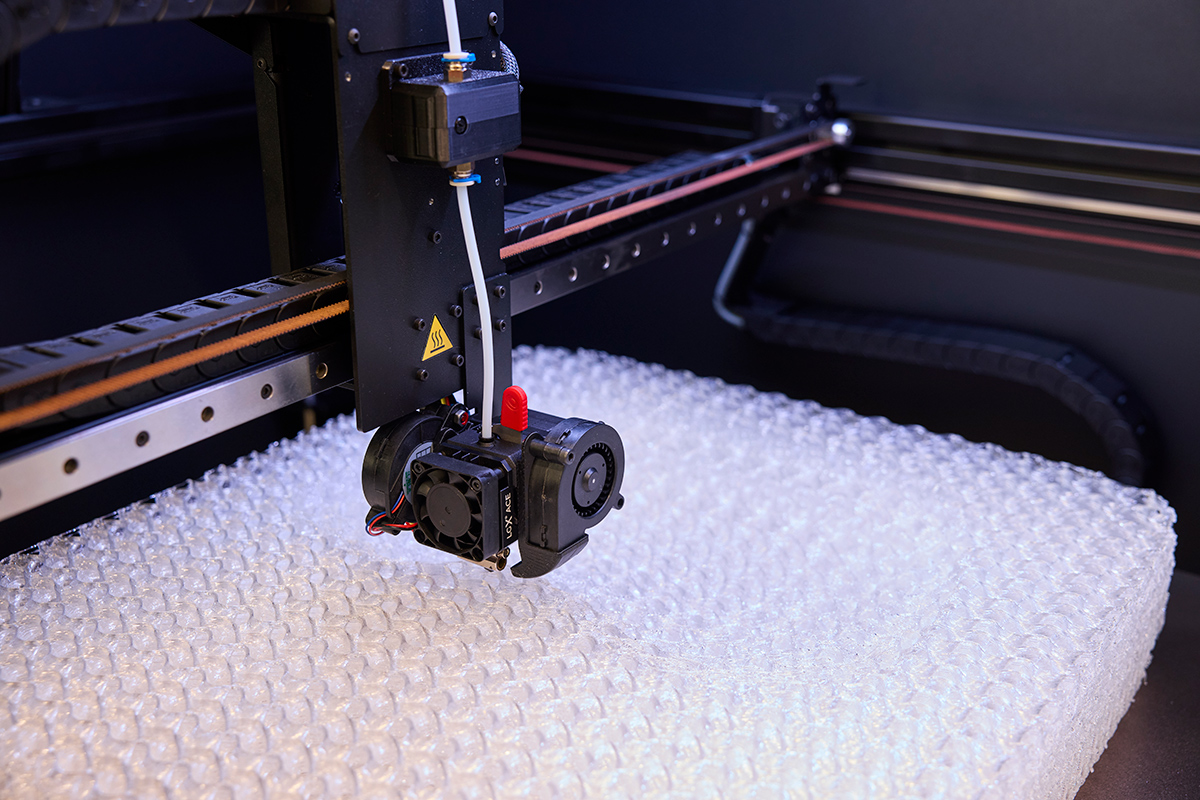

FDM 3D printing for orthopedic products

Fused Deposition Modeling (FDM) is at the core of our production process—because it delivers what orthopedic professionals need: precision, efficiency, and a clean, scalable workflow.

By adopting a fully digital process, we eliminate messy, manual steps like molding or cutting. This not only keeps the workspace clean but also streamlines production—saving time, reducing errors, and enabling fast iterations.

FDM makes mass customization simple. Each product is printed directly from a digital design, allowing for tailored fit and performance without adding complexity or cost. The process is easy to scale and cost-effective even for one-off items.

And because additive manufacturing builds layer by layer—rather than cutting away from a block—material waste is significantly reduced. The use of a single material also supports easier recycling and more responsible resource use.

Smart, clean, and ready to scale—FDM helps us deliver better outcomes, faster.

Patented technology at the core

Programmable Foam enables precise, customized designs with minimal waste and no need for manual shaping—bringing together performance, efficiency, and sustainability in one digital workflow.

Our ADDCAAM™ technology—also patented—introduces a unique multi-directional print strategy that strengthens internal structures without increasing material usage. It’s engineered for applications where durability, accuracy, and cost efficiency are critical to outcomes.

Printing in polypropylene means that whether flexibility or rigidity is needed, the s orthopedic professionals get the tools to fine-tune properties for each individual case. This means they can prioritize both treatment efficacy and patient comfort—an essential combination for long-term success.