3D printed molded wheelchair seat

Programmable Foam® seating adapts to the unique shape, posture, and pressure needs of each wheelchair user. Offering a cleaner, more comfortable, and sustainable alternative to traditional molded seats.

Smarter seating, made possible by Programmable Foam®

Optimal pressure distribution

Better hygiene

Accurate positioning

Explore the advantages gained through a digital workflow:

- Fewer adjustments over time: Durable structure keeps its shape and function longer.

- Washable: A seat can be safely rinsed by hand under cold water or placed directly in the washing machine for easy cleaning.

- Fire retardant: Safer than a seat produced from traditional foam. When exposed to open flames, it melts instead of burning.

- Replicable: It can be a true copy if you need a second seat. The digital file can easily be reprinted or adjusted.

- Micro-climate and ventilation: Improve comfort, and prevent moist skin.

- Easy mounting: Apply solid sections for mounting by integrating bolt-ready areas directly into the design for easy installation.

- Minimal material waste: Our digital process eliminates foam offcuts, supporting your sustainability goals, up to 99% less waste than the traditional foam seat.

When your life depends on wheelchair seating

Download our white paper and learn why microclimate is a critical and often underestimated factor in wheelchair seating. Based on clinical research, standardized testing, and real-life user experiences, the paper explains how heat, moisture, and airflow directly affect pressure injury risk, hygiene, and long-term health.

Designs that deliver

Discover how professionals are using our technology to solve complex seating challenges—delivering better outcomes for their users, with precision and confidence.

The story of Bernd and his 3D printed seat

Bernd is 23 years old and an active young man who lives with his parents on a farm. He is cognitively intact but spends his day in a wheelchair because he has spasticity. Spasticity is characterized by increased muscle tone and stiffness, resulting in involuntary muscle contractions, movement difficulties, and discomfort. It is often associated with conditions such as cerebral palsy, multiple sclerosis, and spinal cord injury.

Create a better seating today

Print on demand or power your own production line

3D print service

Production solutions

Reduce waste with up to 99%

Switching from traditional foam to 3D-printed Programmable Foam® for molded wheelchair seats drastically cuts production waste. Traditional methods can discard up to 50% of the material, while additive manufacturing uses only what’s needed, leaving nearly zero waste. In a recent side-by-side display, one seat left a bag of foam scraps, the other, just a small string of filament.

This shift also supports all four key waste-reduction strategies:

- Prevention through digital precision

- Reduction by using less material

- Recycling thanks to a single recyclable base

- Reuse of leftover material

Journey into the digital transformation

- Produce superior seats and cushions

- Save time and labor in the production process

- Achieve cost-effective production

What is a 3D printed molded seat with Programmable Foam®?

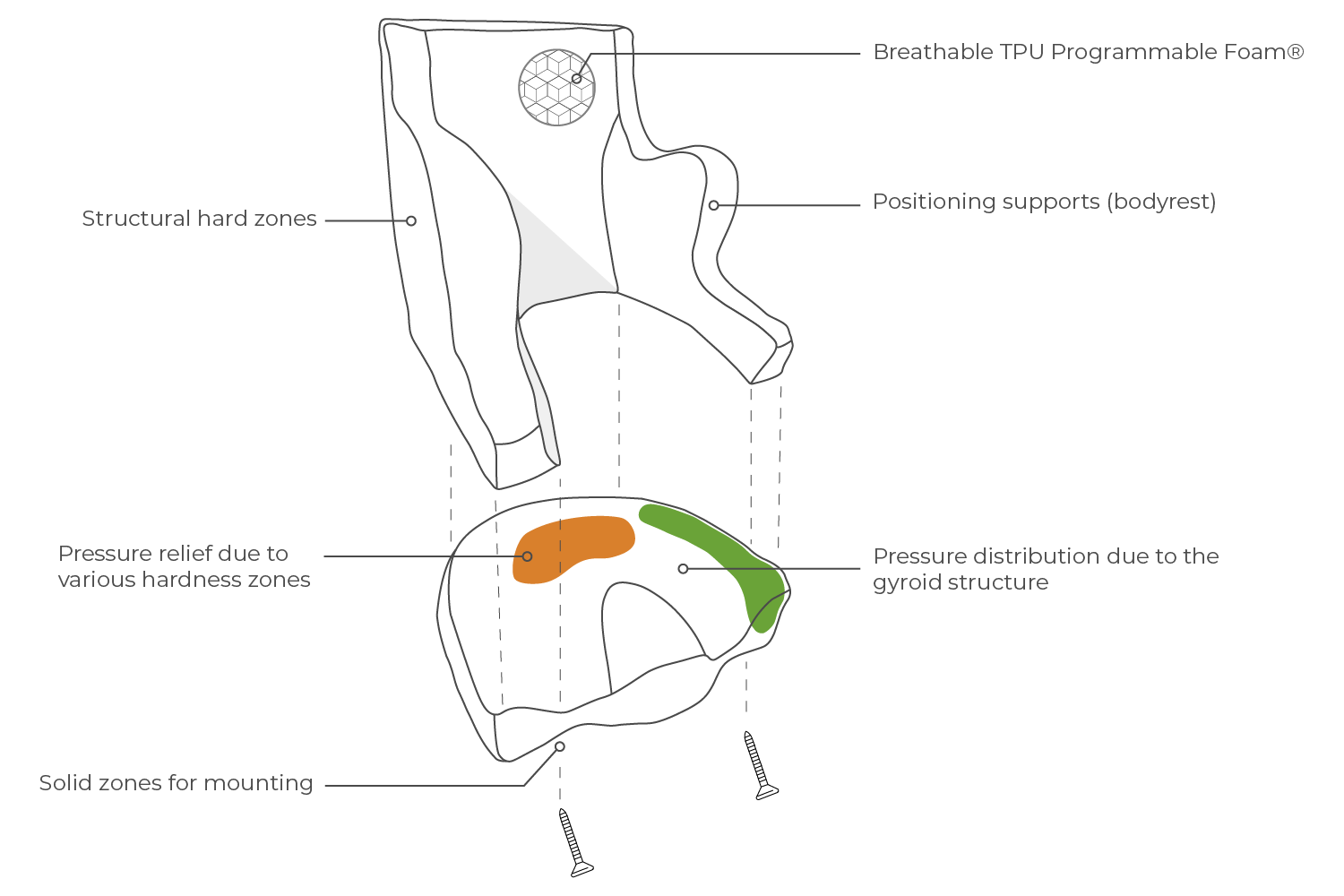

A 3D-printed molded seat is a custom-designed seating solution made to match the body contours and posture of a wheelchair user. Using our Programmable Foam® technology, we digitally control internal patterns during the 3D printing process, resulting in a personalized orthopedic positioning seat with variable softness, support, and flexibility built in.

Unlike traditional molded foam seats, there’s no carving, gluing, or laminating. You get a cleaner, more consistent result that fits perfectly from day one.

A molded seat offers optimum comfort for the user and takes the micro-climate to the next level in devises, such as

- Custom wheelchair cushions and backrests.

- Positioning seats for pediatric or complex postural needs.

- Specialty seating systems for sports or active users.

Frequently asked questions

What is a 3D-printed molded seat with Programmable Foam®?

It’s a seating solution that’s custom-designed and 3D printed to match a wheelchair user’s shape, posture, and pressure needs. Our Programmable Foam® technology enables variable softness and support directly in the design—no carving, gluing, or laminating required.

Why is it better than a traditional molded seat?

Unlike traditional foam seats, our solution is digitally designed and printed with integrated hard and soft zones. This results in improved hygiene, pressure relief, positioning, and long-term durability—with up to 99% less waste in production.

What materials are used to print the seats?

We use our specially developed CREAtech filament—a flexible TPU (thermoplastic polyurethane) designed to optimize both performance and durability. It’s washable, fire retardant (compliant with EN 1021-1 and EN 1021-2), and highly sustainable. Additive manufacturing with CREAtech produces zero dust and minimal waste, making it suitable even for clean office environments.

What types of seats can be made with Programmable Foam®?

Programmable Foam® is used for:

- Custom wheelchair cushions and backrests.

- Positioning seats for pediatric or complex postural needs.

- Specialty seating systems for sports or active users.

How does it help reduce pressure sores?

The internal structure is designed to distribute pressure evenly using a mix of soft and supportive zones—tailored to the user’s anatomy. This lowers the risk of pressure injuries significantly.

Is the seat easy to clean?

Yes. The surface does not absorb fluids and is easy to wipe. You can rinse the seat under cold water or even put it in the washing machine.

What about hygiene and safety?

The seat is both washable and fire retardant. If exposed to flame, it melts instead of catching fire—making it a safer choice.

Can I reproduce the same seat later?

Absolutely. Once designed, the digital file can be reused to create an identical seat—or updated for adjustments—without starting from scratch.

How is the seat mounted?

Mounting is easy. Bolt-ready areas can be integrated directly into the design, making installation fast and secure.

Does it support sustainability?

Yes. Compared to traditional manufacturing, 3D printing with Programmable Foam® can cut production waste by up to 99%. It supports circular economy goals by using only the material needed, enabling recycling, and avoiding foam dust in the production environment.

How do I get started with 3D-printed seating?

Start by reaching out to us or one of our partners. We’ll guide you through the fully digital workflow—from design to delivery—so you can offer smarter, more sustainable seating to your users.