Create it REAL and Vitalitecs bring advanced digital orthopedic production to Mexico

Create it REAL is excited to announce a partnership with Vitalitecs, based in Monterrey, Mexico. With the partnership, we provide access to advanced digital production technologies for orthotics, prosthetics, and patient-specific medical devices across Mexico. The collaboration positions Vitalitecs as both a reseller of Create it REAL’s Embrace production solutions for multiple devices, like custom seating aids, diabetic insoles, and corrective braces. and a local 3D print service provider, offering orthopedic professionals multiple options to adopt digital workflows tailored to their clinic or workshop needs.

This dual role ensures that professionals can either bring production in-house with full support and training or leverage Vitalitecs’ local service to produce patient-specific devices on demand, thereby removing traditional barriers to adopting digital manufacturing, such as high upfront investment, technical expertise, or limited production capacity.

“Partnering with Vitalitecs allows us to reach the Mexican orthopedic market with technology that has proven performance and clinical relevance. Vitalitecs has over a year of hands-on experience with Programmable Foam® technology, understanding both the technical capabilities and the real-world clinical applications. Together, we can help professionals save time, reduce waste, increase patient capacity, and deliver high-quality, reproducible results.”

— Jacob Nissen, CEO of Create it REAL

Innovation with purpose

At the core of this partnership is Programmable Foam® technology, a patented, purpose-engineered material that elevates traditional foam. Unlike conventional foam, which can vary from batch to batch and requires manual adjustments, Programmable Foam® enables precise control of density, flexibility, and performance, ensuring consistent results across devices.

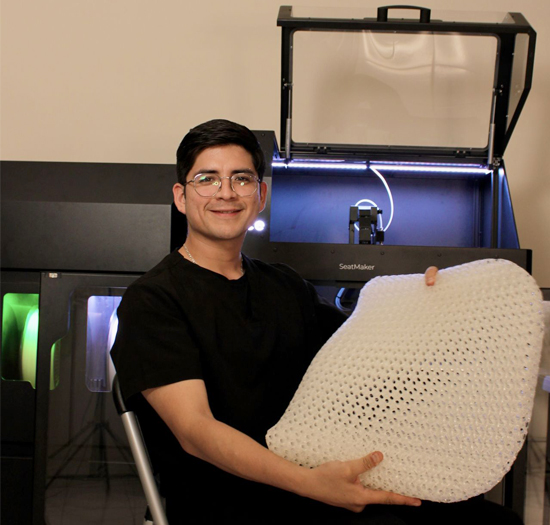

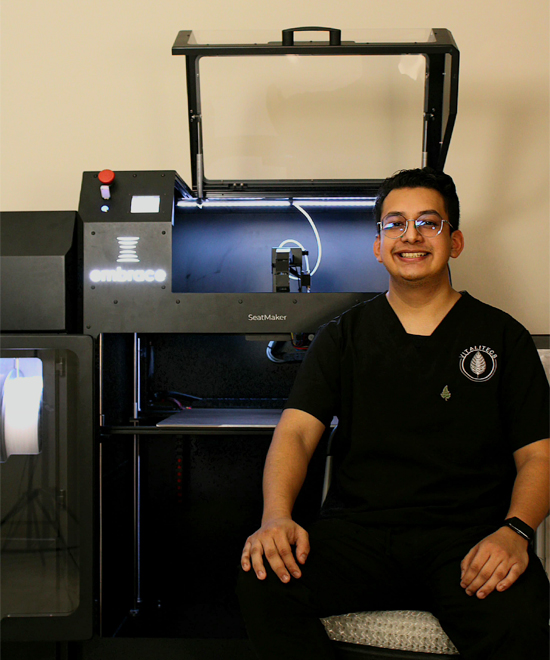

Vitalitecs has spent more than a year integrating Programmable Foam® into its production process, using a dedicated 3D printer to produce seating aids and diabetic insoles. The technology is tested and certified, making it suitable for clinical applications where quality and patient safety are critical.

“After more than a year working directly with Programmable Foam®, we are confident in both its performance and its relevance for custom diabetic insoles and seating aids,” says Jose Juan de Leon, CEO of Vitalitecs.

“We see strong interest from clinics and workshops that want to modernize production to increase quality and efficiency while maintaining craftsmanship. Our partnership with Create it REAL allows us to offer both production solutions and a local 3D print service, giving professionals the flexibility to adopt digital workflows at their own pace.”

Efficiency, sustainability, and patient outcomes

The benefits of digital workflows extend beyond innovation. By adopting Embrace production solutions, orthopedic professionals can:

- Save time and increase patient capacity, reducing manual labor and streamlining production steps.

- Optimize material use and reduce waste, thanks to precise digital design and production planning.

- Ensure consistency and quality across all devices, improving patient comfort, durability, and clinical outcomes.

This combination of efficiency, sustainability, and patient impact addresses growing pressures in orthopedic care, where clinics and workshops must balance high-quality treatment with productivity and resource management.

Introducing the Embrace product line

The partnership brings Create it REAL and Vitalitecs closer together, aligning technology, production expertise, and market development in Mexico. As part of the collaboration, both companies look forward to introducing the Embrace product line to the market. Embrace offers custom seating and cushioning solutions designed to improve comfort, functionality, and clinical effectiveness, all powered by Programmable Foam® technology.

Together, Create it REAL and Vitalitecs are enabling a new era in orthopedic production, where advanced technology, sustainability, efficiency, and patient-centered design come together to deliver real-world benefits for clinics, workshops, and patients across Mexico. For more information, please don’t hesitate to contact the marketing manager, Mette Kristensen, at [email protected].

“After more than a year working directly with Programmable Foam®, we are confident in both its performance and its relevance for custom diabetic insoles and seating aids”

— Jose Juan de Leon, CEO of Vitalitecs