How can we free up time for patients?

Across Europe, orthopedic clinics are busier than ever. Waiting lists grow, technicians juggle multiple tasks, and the pressure to deliver high‑quality, customized devices within a limited timeframe continues to rise. It is not a lack of dedication; it is a lack of hours in the day. However, there is also a concern that patients may not receive the best service they need.

We assume that behind this reality lies a deeper challenge. Orthopedic production still relies heavily on craftsmanship, involving manual foam shaping, plaster casting, and labor‑intensive fitting. These methods are reliable, but they take time. With a shrinking pool of trained professionals, every new patient adds to the workload. In the United Kingdom alone, the prosthetics and orthotics workforce includes about 1,766 professionals. Yet, with 109 vacancies and an estimated shortfall of 142 to 477 people compared to World Health Organization benchmarks, the sector is under significant pressure.

The question is not whether clinics are doing enough. Will the younger generation settle for an old‑fashioned production method while more modern, fully digital workflows are already available and showing measurable progress in patient care? And will patients settle for the traditional product when a modern, up‑to‑date technology offers something better?

Will recruitment become easier?

The demand for orthopedic devices is on the rise. Populations are aging and awareness of the benefits of custom support devices has grown. But while demand rises, the available workforce has not kept pace. Let’s take a look into the crystal ball of what to expect right now and from the next generations.

- Recent studies in Europe and the United Kingdom show persistent vacancies in prosthetic and orthotic roles. Many clinics struggle to recruit new staff, and a significant share of technicians plan to leave the field within a few years.

- Part of the reason is that the job has remained largely unchanged for decades. Orthotic technicians spend long hours shaping foam, cutting, sanding, and cleaning up materials. This process is time-consuming and physically demanding.

- For younger professionals entering the workforce, this manual and workshop-heavy environment can feel outdated.

- The next generation has grown up with digital tools and expects technology to be part of their daily work. They seek cleaner, more flexible, and more automated processes. They value efficiency and modernity as much as craftsmanship.

- As the workforce becomes smaller, we need to explore less labor-intensive production methods and smarter crafting techniques.

Are orthopedics ready for the change?

“The pioneering clinics are already using the new technologies, and their patients love it,” explains Jacob Nissen, CEO of Create it REAL. “But when we approach some of the established operators in the clinics, they are simply too busy to investigate new methods that could change their work and free up time for patient care. They must recognise that there is a need to change their way of working and prioritize the adoption of new technology to improve their current unsustainable situation and attract the next generation of professionals.”

New graduates are eager to work with digital design, automation, and advanced materials that are already transforming industries from dentistry to manufacturing. They do not want to learn outdated craftsmanship when better and more effective production methods are available now. In orthopedics, however, many clinics still rely on manual fabrication. That gap between traditional craftsmanship and digital potential is becoming a barrier to recruitment.

A purely hands‑on workflow limits scalability and flexibility. When an experienced technician is unavailable, the process can stall. When new staff join, they require months of training before working independently. Digital workflows, by contrast, make skills transferable and processes consistent.

We are confident to claim that the clinics that embrace digital tools today will attract and retain the next generation of professionals.

Digital workflows work today

Digitalization in orthopedics is no longer an experimental endeavour. The tools are available now, and clinics using them are already seeing results.

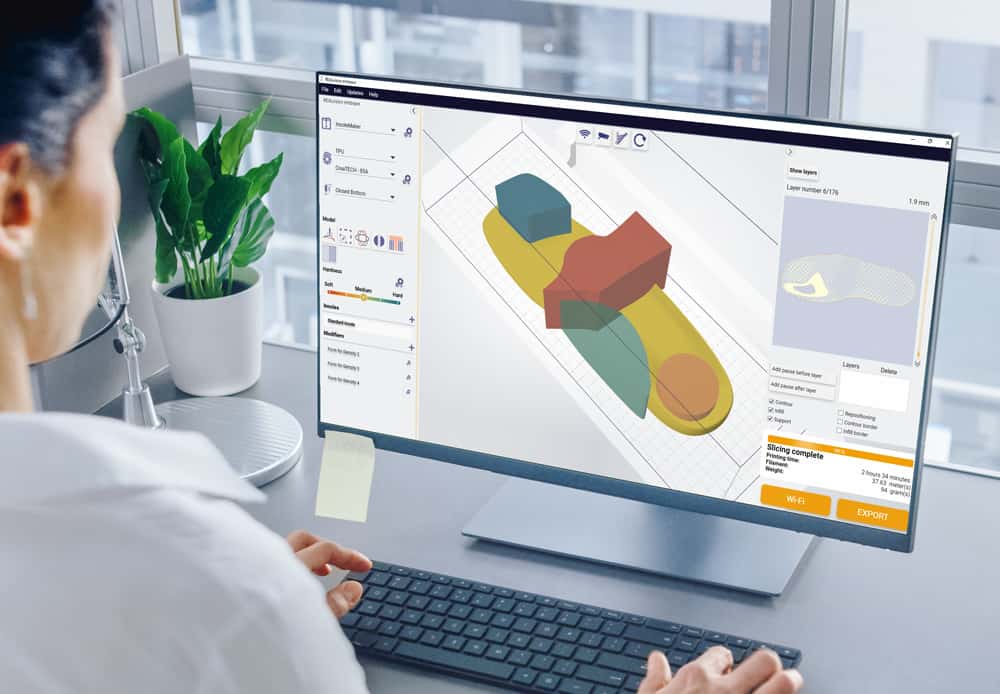

- Three-dimensional scanning replaces plaster casting, providing clinicians with a precise digital model in just minutes.

- Software-based design replaces manual shaping, enabling easy adjustments, instant feedback, and consistent geometry every time.

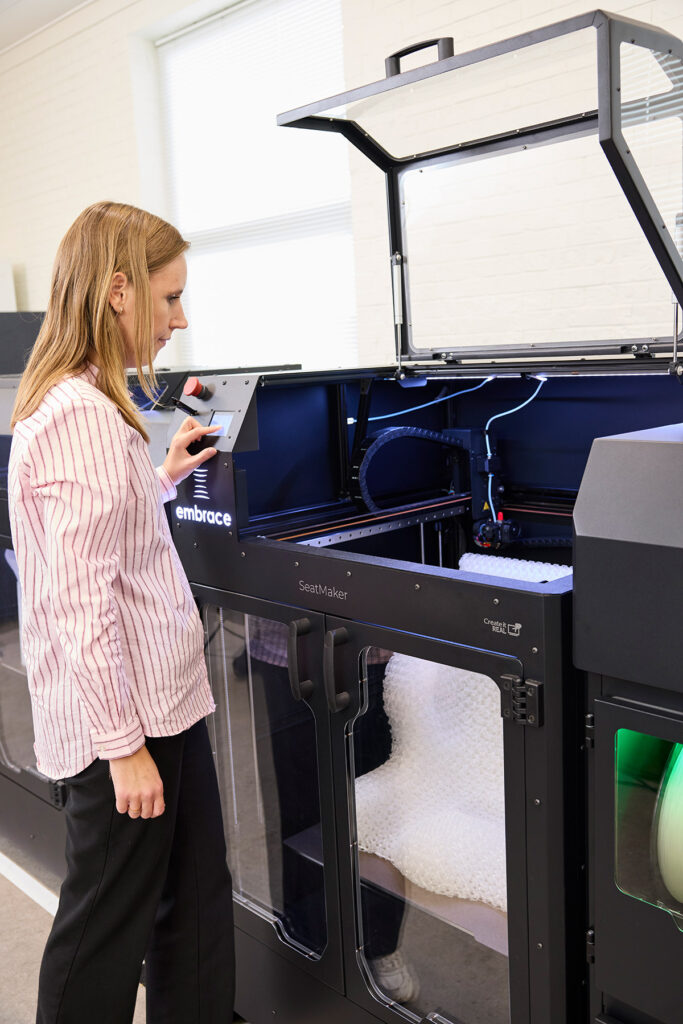

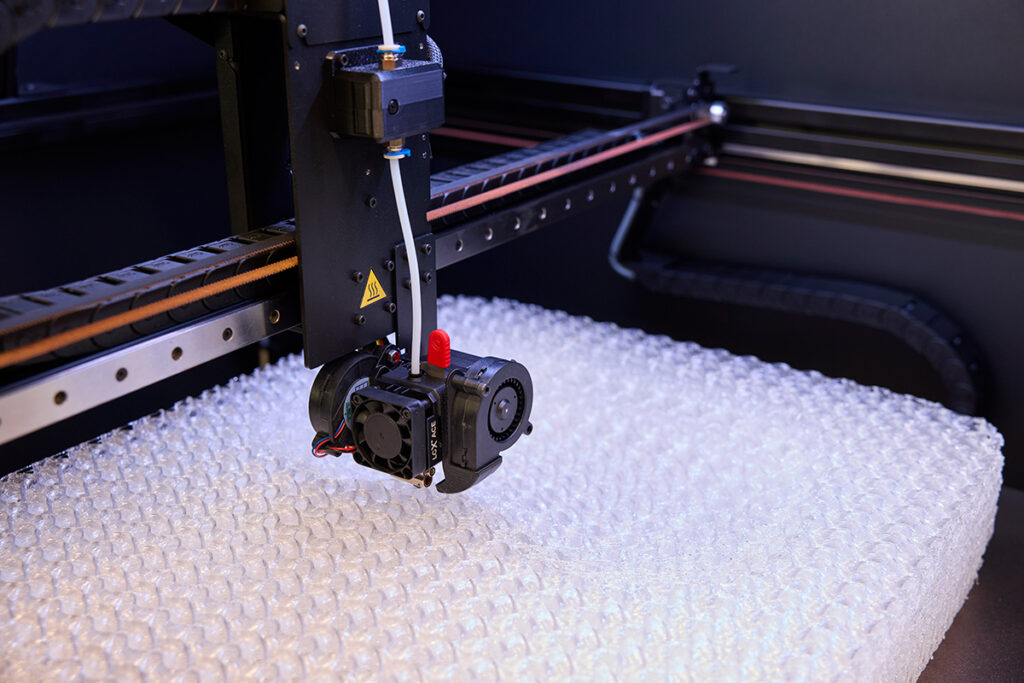

- Three-dimensional printing with materials such as Programmable Foam replaces manual foam cutting, producing clean, reproducible, patient-specific devices while generating minimal waste.

By combining these technologies, clinics can streamline workflows, reduce physical labour, and allocate more time to focus on what truly matters: the patient. Additionally, achieve a lower production cost per unit.

Freeing up time for patients

The ultimate goal of any orthopedic clinic is to help people move, sit, or stand more comfortably. Digital workflows directly support that goal.

When production becomes less labour‑intensive and more predictable, clinics can handle more patients without extending working hours. Devices can be delivered in days instead of weeks. Adjustments become easier because every product is stored as a digital file, ready to be remade or modified instantly.

Patients benefit from shorter waiting times, better comfort, and improved hygiene. Clinics benefit from a calmer, more organised environment and reduced staff stress. When clinicians spend less time on fabrication, they can allocate more time to where it truly matters: with the patient.

A modern profession for a modern generation

To secure the future of orthopedic care, the profession itself must evolve. By embracing digital workflows, clinics can transform their image from traditional, one-on-one workshops to modern, high-tech healthcare environments.

This shift makes the profession more attractive to new recruits, including individuals who view themselves as both healthcare technologists and craftspeople. It also creates opportunities for upskilling existing staff, offering them new competencies and career growth within a familiar field.

Digitalization is not only about efficiency — it is about ensuring that the next generation of professionals sees orthopedics as a future‑ready field worth joining.

“The pioneering clinics are already using the new technologies, and their patients love it"

— Jacob Nissen, CEO Create it REAL

Moving forward

Transitioning to a fully digital workflow doesn’t happen overnight — but it can start today. Every clinic that adopts three-dimensional scanning, digital design, or three-dimensional printing takes a decisive step toward a more sustainable, cost-effective, and responsible approach to working.

Clinics that embrace this shift early don’t just cut production costs and material waste — they free up the hands and minds of their teams, unlock more time for patient care, and position themselves as leaders in a new era of technology-enabled, patient-centered services.

If you think the cost of change is high, consider the far greater cost of doing nothing. Clinics that move forward will also attract the next generation of professionals — young, modern, and motivated by the opportunity to use technology to make a real difference every day.