From manual to digital workflow – how C-ortho creates braces today

“Seeing a child stand up straighter, move more freely, or smile because they feel good in their brace — that’s what makes the work worthwhile.” For Catherine Christiaens, founder and owner of C-ortho, this is more than a statement; it’s the driving force behind decades of work in orthopedic brace design.

The work is complex: correcting a spine or posture is a three-dimensional process, with multiple points of engagement that must be carefully balanced for each patient. Early in her career, Catherine relied on traditional plaster methods, shaping each brace by hand. The first step toward digitalization came with milled torsos—3D scans of patients turned into physical models she could still touch and shape by hand. This hybrid approach enabled her to leverage technology while retaining the tactile expertise she had developed over years of practice.

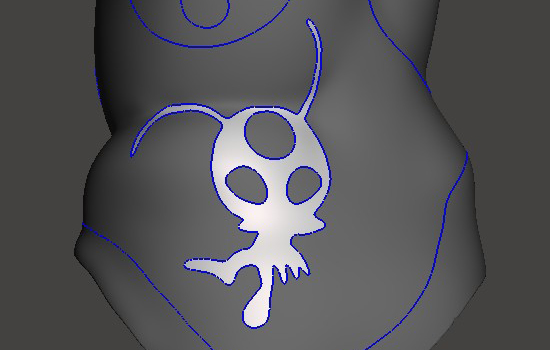

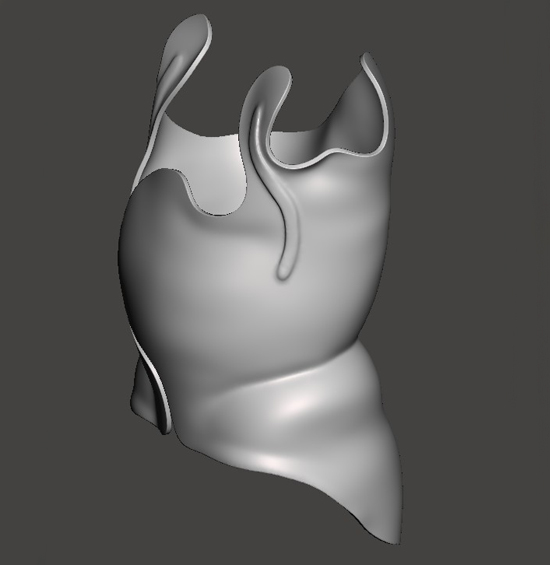

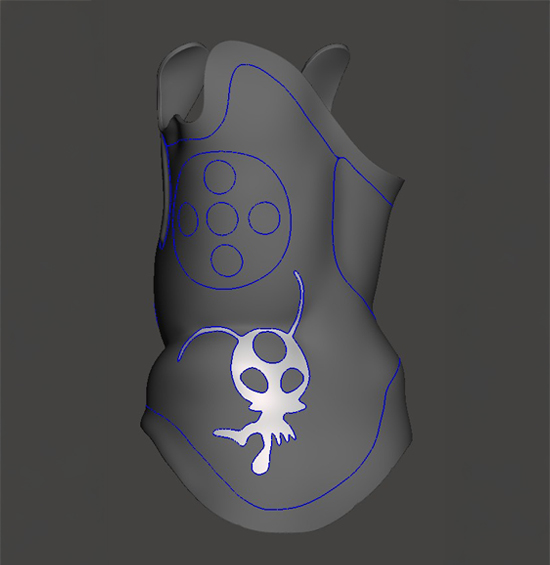

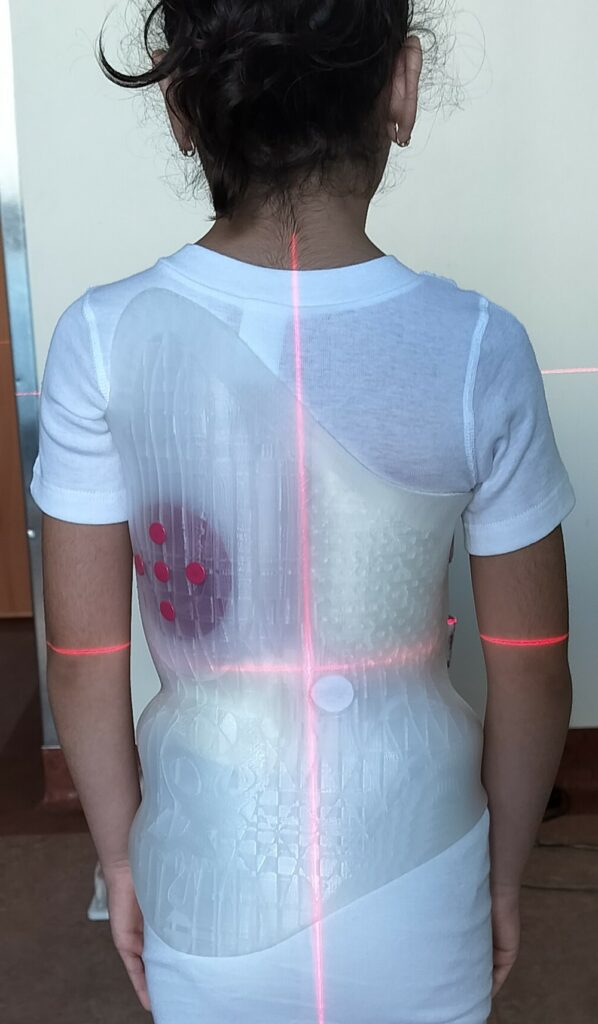

Today, her workflow is fully digital thanks to her cooperation with Shapemakers in the Netherlands. Complete 3D scans, precise modeling, and 3D printing allow braces to be tailored to each patient’s anatomy, while ensuring consistency and minimizing material waste. Yet even in this data-driven environment, Catherine blends technical precision with her artistic eye, creating braces that are not only corrective but also smooth, comfortable, and discreet.

C-ortho stands for care, corsets, and a circular production approach built on re-use, recycling, and re-design — all with the goal of making braces as sustainable as possible.

Conditions treated by C-ortho:

- Idiopathic scoliosis – progressive spinal curvature often appearing during adolescence.

- Other spinal deformities – including congenital or neuromuscular scoliosis and postural asymmetries. Supporting children and adolescents to improve alignment, comfort, and mobility.

- Spinal trauma–fractures, stabilization of the spine.

Note: Each brace is tailored to the patient’s unique anatomy and growth stage, ensuring effective correction while maximizing comfort and compliance.

Traditional Handcrafted Braces

Early methods:

Catherine Christiaens began her career creating braces entirely by hand. Using plaster casts of each patient, she would mold and shape the material herself, starting from scratch every time. This hands-on approach allowed her to apply her artistic skill and deep anatomical knowledge directly to the work.

Challenges:

- Time and effort: Each brace required hours of labor, from taking measurements to shaping and smoothing the final piece.

- Material limitations: Traditional plastics, such as high-density polyethylene, were heavier and prone to losing their shape over time. Certain areas, like the shoulders, tended to deform under pressure, meaning the brace could become less effective and require adjustments.

- Environmental concerns: The plaster and material waste generated by traditional methods added complexity to her workflow.

- Impact on adolescents: For young patients, especially during adolescence, the plaster casting process can be intimidating or uncomfortable. This added an emotional layer to the already complex treatment.

Hands-on advantages:

Despite these challenges, the traditional workflow provided Catherine with a tactile understanding of each patient’s body, enabling precise anatomical fitting and smooth finishes. However, the constraints of the material, time, environmental concerns, and patient comfort highlighted the need for a more modern approach.

First steps into digital: Milled torsos and hybrid workflows

Catherine’s journey toward digital brace production began with 3D scanning. By capturing each patient’s torso digitally, she could generate precise models without the labor-intensive process of using plaster. From these scans, milled torsos were created—physical replicas she could hold, touch, and refine by hand.

This hybrid approach allowed her to combine the accuracy of digital technology with the artistry and expertise she had honed over years of hands-on work. “Even though I was working digitally, being able to touch the model with my hands helped me understand each body and make corrections in a way that felt natural,” she explains.

The benefits were immediate: adjustments could be made without starting from scratch, the workspace became cleaner, and patients—particularly adolescents—experienced a less invasive, more comfortable process. For Catherine, it was a crucial step in bridging traditional craftsmanship with emerging digital capabilities, retaining both precision and a human touch. However, the torsos are also accumulating waste, so the next step is to become fully digital.

Precision and comfort through data-driven design

The shift from handcrafted braces to a fully digital workflow has allowed Catherine to create more precise and consistent results while maintaining her artistic intuition. By scanning the patient’s torso, she now works with accurate digital models that can be adjusted with fine detail before production. This step not only enhances the quality of each brace but also facilitates the documentation and comparison of treatments over time, thereby fostering a more data-driven approach to patient care.

Digital tools haven’t replaced her expertise; they have enhanced it. She still applies her understanding of the body’s complex three-dimensional corrections, deciding exactly where pressure or relief should be applied. What has changed is that every adjustment can now be visualized, measured, and refined on screen before being produced.

“Now I can combine my knowledge and my artistic side with data. The software gives me precision, but I still decide where to push and where to relieve. It’s still my hands, just in another way.”

— Catherine Christiaens

Sustainability is another important factor in her workflow. While earlier methods of milling positive models from foam already represented a move away from messy plaster casting, they generated large amounts of dust and waste. By transitioning to direct 3D printing, Catherine has eliminated the need for single-use torso models and significantly reduced material waste. Making her process not only more efficient but also more environmentally responsible.

Catherine’s approach blends digital precision with hands-on expertise. Every brace begins as a detailed digital model, yet her experience and artistic understanding guide how the brace will fit and correct the body. This method allows her to create braces that are both highly effective and comfortable, while keeping the patient’s comfort and individuality at the center of the process.

From collaboration to care is teamwork

Catherine emphasizes that creating effective braces is never a solo task. Her work is closely coordinated with doctors, physiotherapists, and sometimes psychologists to ensure that each patient receives a treatment plan tailored to their needs and lifestyle. “It’s not enough to give a brace and hope it works,” she explains. “We need to understand the child, their parents, and how everyone can contribute to make it succeed.”

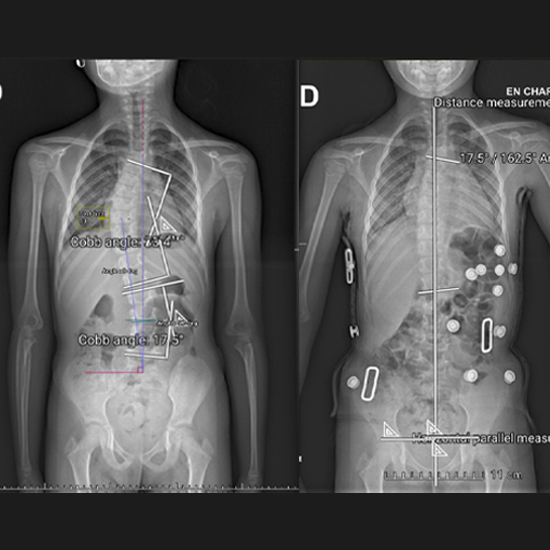

The collaboration starts with careful evaluation of X-rays and body measurements, followed by joint discussions on how to approach the correction. Catherine then designs the brace digitally, but always with input from the medical team.

After the patient receives the brace, follow-up appointments and X-rays are scheduled at one month, four months, and periodically thereafter to monitor growth and compliance. This continuous feedback loop enables the team to make incremental adjustments, ensuring the brace remains effective while being as comfortable as possible.

Catherine points out that adolescence can be a challenging period for compliance. Regular meetings and communication with the patient and their parents are crucial to maintaining motivation. She notes that witnessing a young patient struggle or succeed in wearing the brace underscores the importance of a coordinated approach to treatment. The goal is to combine medical expertise, orthotic craftsmanship, and empathy to achieve the best possible outcome for each child.

Step-by-step treatment workflow

- Initial evaluation: Doctors and physiotherapists assess the patient’s condition, take X-rays, and measure body posture.

- Collaborative planning: The medical team discusses treatment strategy with Catherine, identifying key correction points and goals.

- Digital design: Catherine creates the brace in a digital workflow, integrating data from X-rays, measurements, and prior treatments.

- First fitting: The patient tries the brace; Catherine smooths edges and marks areas for adjustment, noting any comfort issues.

- Refinements: Adjustments are made to optimize fit, comfort, and correction, taking into account the patient’s body and activity.

- Follow-up monitoring: Patients return after one month, four months, and periodically; X-rays and measurements track growth and the effectiveness of the brace.

- Ongoing support: Catherine and the medical team maintain open communication with patients and their families, addressing compliance and comfort throughout the treatment process.

Working with 3D printed polypropylene braces

Catherine’s shift to 3D printed polypropylene braces marked a new era in both precision and patient comfort. Unlike traditional materials that could deform over time, the polypropylene braces maintain their shape, ensuring consistent correction and a better fit. With careful digital design, each brace can closely follow the patient’s anatomy, applying the right pressure points to correct the spine effectively while allowing children to move and interact naturally.

From a technical standpoint, the braces are lighter and easier to adjust. Catherine can make small refinements with a heat gun where necessary, ensuring the brace fits smoothly without compromising its structural integrity.

She emphasizes the importance of following the doctor’s recommendations for wearing time, explaining that the difference in treatment effectiveness is significant. Wearing the brace for 12 hours a day has only a small influence on the spine, whereas 18 hours a day achieves about 80 percent of the possible correction. Extending wear up to 22–23 hours increases correction to roughly 90 percent, but the most crucial jump is between 12 and 18 hours.

Catherine emphasizes that patient comfort is crucial to achieving adherence, and the lighter, discreet design of the 3D-printed braces facilitates their wearing by children, especially adolescents, as prescribed. Parents also play a vital role in encouraging consistent use, particularly for older teens, ensuring that the brace can deliver its full therapeutic benefit. These insights align with Mathew Potts’ article, which emphasizes that comfort and usability in 3D-printed braces are crucial for patient adherence and optimal outcomes.

The combination of accurate 3D printing, durable material, and careful attention to the patient’s experience allows Catherine to provide braces that are both effective and comfortable, supporting better outcomes throughout the treatment.

Key highlights of 3D printed polypropylene braces

- Maintain shape over time, ensuring consistent correction.

- Digitally designed to follow patient anatomy with precise pressure points.

- Lighter than traditional materials

- Small refinements are possible with gentle heating without compromising the structure.

- A comfortable and discreet design improves patient adherence, particularly among adolescents.

- Wearing for 18 hours a day achieves approximately 80 percent efficiency; wearing for 12 hours provides only a minimal effect.

- Parents play a crucial role in supporting consistent use of braces.

- Insights align with Mathew Potts’ findings on the importance of comfort for adherence and treatment effectiveness.

The future brace design is here now

Catherine Christiaens’ journey from hands-on plaster methods to fully digital, 3D-printed braces demonstrates how innovation can enhance both precision and patient care. Every brace she creates is tailored with meticulous attention to anatomy, comfort, and usability, ensuring that young patients can move freely and adhere to treatment. The combination of digital workflow, durable materials, and collaborative teamwork with doctors, physiotherapists, and families has transformed the way orthopedic care is delivered.

Her work illustrates that technology does not replace expertise—it amplifies it. Catherine can integrate data-driven design with her deep anatomical knowledge and artistic skill, creating braces that are both corrective and comfortable. By reducing waste, Catherine not only improves efficiency but also contributes to a more responsible and patient-friendly practice. The focus on patient comfort, discreet design, and adherence ensures that each brace fulfills its therapeutic potential, making a tangible difference in the lives of children and adolescents.

Catherine’s work exemplifies a future where orthopedic care blends technology, craftsmanship, and empathy, delivering better outcomes while keeping the child’s experience at the center of treatment. She is seeing patients in Belgium and can be contacted.

Key takeaways:

- Fully digital workflows enable highly precise and personalized braces with consistent results.

- 3D-printed polypropylene braces maintain their shape, are lighter.

- Correct application of pressure points is crucial for effective correction while allowing movement.

- Comfort and discreet design significantly improve adherence, especially for adolescents.

- Wearing the brace for 18 hours a day achieves optimal efficiency, while wearing it for 12 hours provides a minimal effect.

- Parental support is crucial in encouraging consistent use and adherence.

- Collaboration between orthotists, doctors, physiotherapists, and psychologists ensures comprehensive care.

- Sustainability is improved by reducing material waste and eliminating the need for single-use torso models.