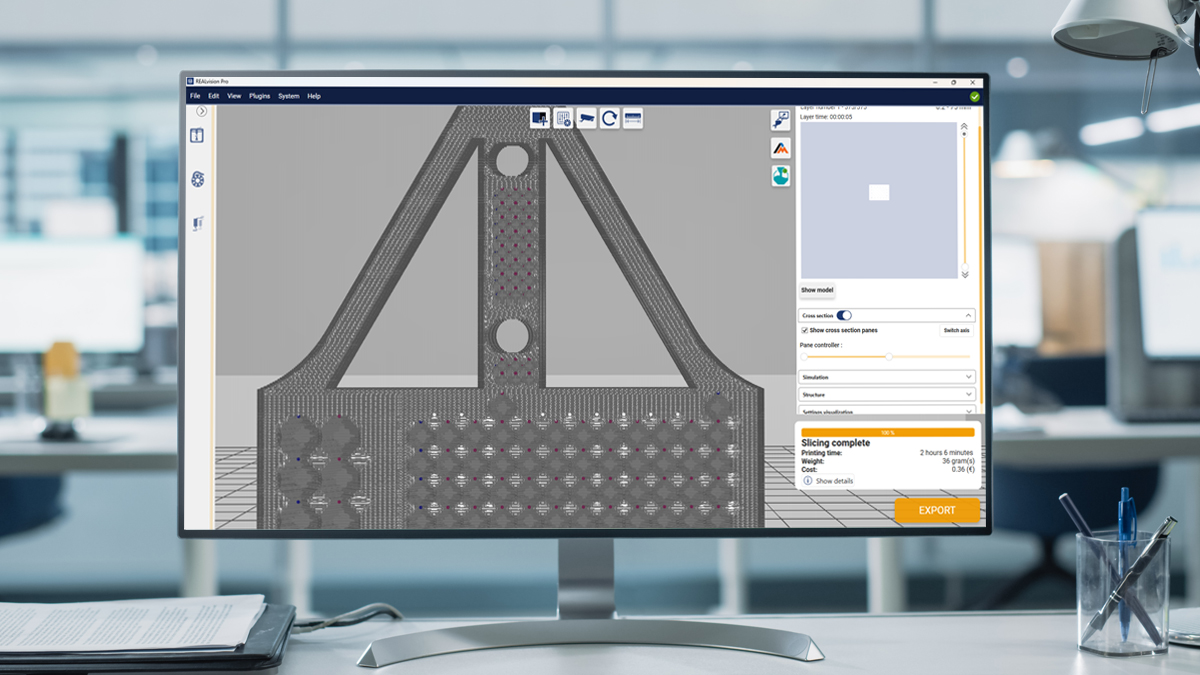

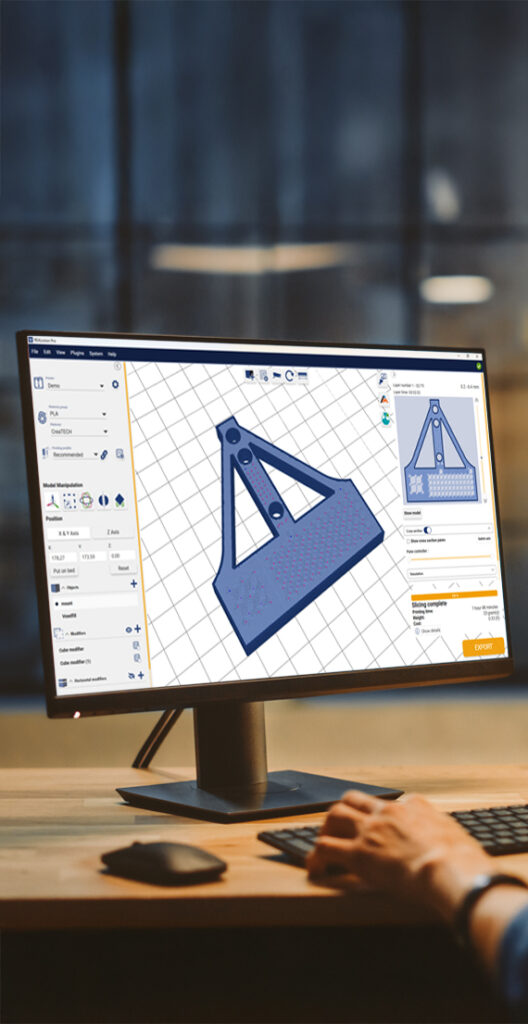

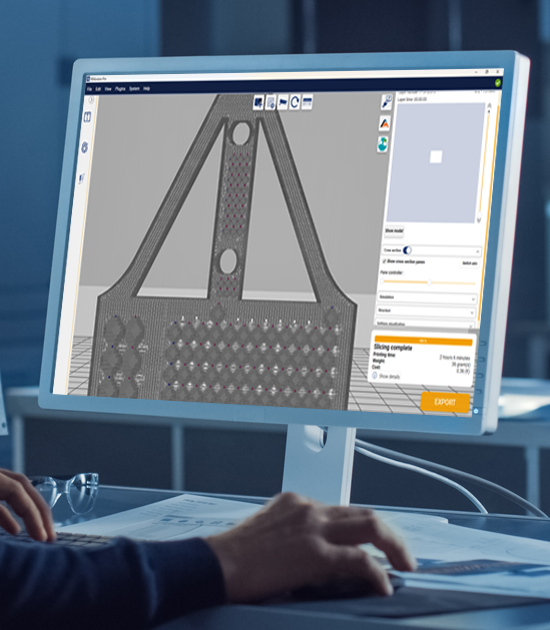

Advanced Voxelfill technology available through REALvision Pro

October 2025.

AIM3D and Create it REAL are proud to announce the early access phase release of Voxelfill, an advanced new plugin for REALvision Pro that makes stronger FDM 3D printing accessible to professionals and hobbyists alike.

For years, one of 3D printing’s most persistent challenges has been Z-strength. Parts often perform well in the XY plane but fail along the Z-axis, where layers bond. Voxelfill changes that—bringing isotropic strength to FDM printing without specialized hardware.

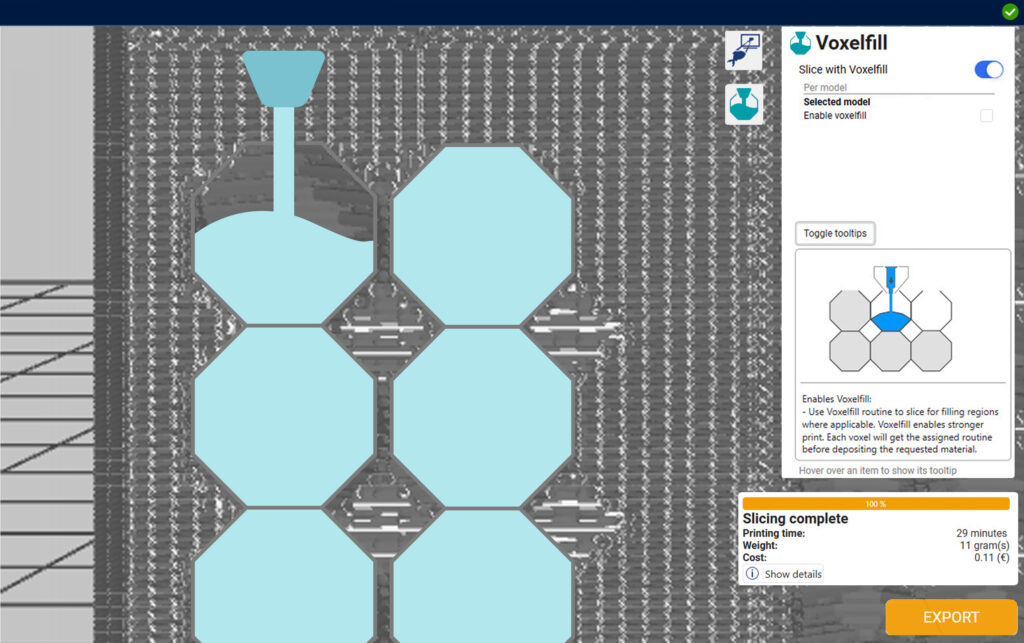

How Voxelfill works

Voxelfill introduces a strategy that combines additive manufacturing with injection-molding principles. Individual voxels are printed conventionally and then filled using an injection-molded technique—directly inside each voxel. The result: reinforced bonding between layers and dramatically stronger parts.

In testing, fiber-reinforced plastics such as PETG GF30 achieved up to 81% of XY strength in the Z direction, unlocking applications that were once out of reach for FDM users.

Why Voxelfill matters

- Breakthrough Z-strength – Stronger parts with reinforced layer bonding

- Fiber-optimized – Perfect for materials like fiber-reinforced PETG

- Production-ready – Validated with real-world use cases and industry leaders

- Accessible innovation – Works on standard FDM printers through REALvision Pro

Accessible innovation for everyone

“How can we make advanced features accessible to everyone?” asks Jeremie Gay, CTO and founder of Create it REAL. “By offering REALvision Pro as a subscription-based, standalone slicer with an open plugin platform, we’ve created a fair-priced gateway to innovation. Voxelfill is a perfect example of how powerful features can be put directly into the hands of users.”

Clemens Lieberwirth, CTO of AIM3D, adds: “With Voxelfill, we are taking a long-standing limitation in additive manufacturing and turning it into an opportunity. Working with Create it REAL made it possible to move from idea to accessible software solution quickly, and the results speak for themselves.”

Trusted by industry leaders

REALvision Pro is already powering production for some of the world’s most innovative additive manufacturing companies, including Meltio, Addman, and 3D Systems. By relying on our platform, these industry leaders demonstrate the scalability, reliability, and advanced capabilities of REALvision Pro in demanding professional environments.

The software is available at realvision.pro and includes a 14-day unlimited free trial. Subscriptions range from single users to standard corporate plans with Strong Print plugins. For organizations with specific requirements, REALvision Pro is also offered as a customized enterprise solution.

Both companies are exhibiting at FormNext, November 18-21. Find NEW AIM3D GmbH in Hall 12.1, E139, and Create it REAL in the Nordic Pavilion, Hall 11.1, E29.

Don’t miss Create it REAL Founder & CTO, Jeremie Gay, on the Technology Stage on Thursday, 20 November 2025, at 11:00 a.m. (Hall 12.1, Booth B49), where he’ll speak about: Bridging the gap between injection molding and FDM with new 3D printing software strategies.

About Create it REAL

Create it REAL is a Danish 3D printing technology company based in Aalborg. With over a decade of experience, the company develops advanced slicing technology and solutions that empower businesses across industries. The REALvision software family combines powerful features with a user-friendly design, making additive manufacturing more accessible, reliable, and scalable. In addition, Create it REAL delivers full production systems for digitalizing orthopedic products, such as spinal braces, and for replacing traditional foams with additive manufacturing and its Programmable Foam technology for products like orthopedic insoles, wheelchair cushions, and molded seats.

About AIM3D

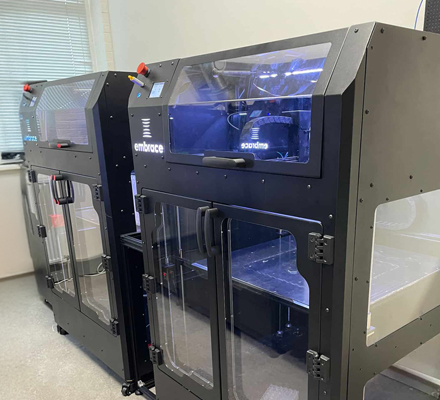

Founded in 2017 in Rostock, Germany, AIM3D develops innovative multi-material 3D printing solutions to reduce the cost and expand the possibilities of additive manufacturing. Backed by a strong academic foundation, AIM3D delivers advanced engineering solutions that are practical and production-ready for plastics, metals, and ceramics.