Esther's new seat makes her smile a lot

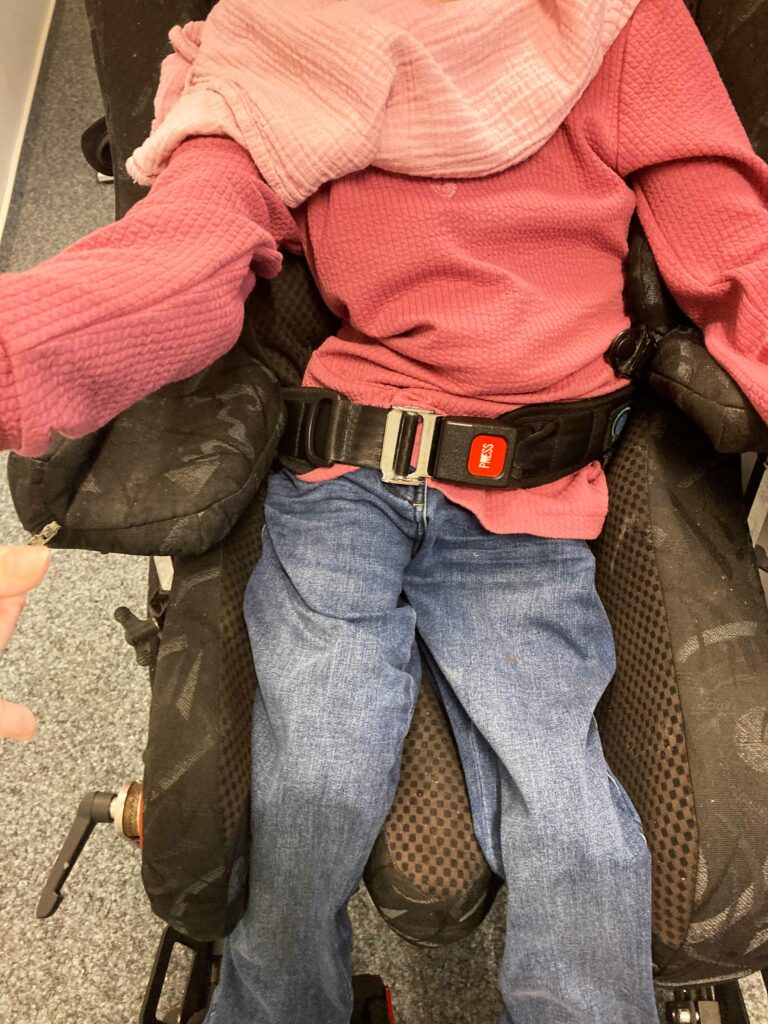

No doubt, getting the right seating solution can be life-changing. For Esther, a 27-year-old woman living with cerebral palsy and severe scoliosis, it meant more than just physical support—it gave her a better position in life, both literally and socially. Today, she smiles more, communicates more effectively, and sits with comfort and dignity in a seat designed specifically to meet her complex needs.

This transformation was far from simple. It is the result of years of professional expertise, deep trust, and the introduction of innovative technology: a fully customized 3D-printed seat made with Programmable Foam®.

Let’s take a step back to explore Esther’s journey—and the critical role her orthopedic specialist, Jan Warnke, played in finding the right fit.

Esther and Jan

Esther is a happy and creative young woman with a passion for music and computers. She enjoys composing music digitally and works on a computer-based project, creating small components for the automotive industry. Esther lives independently in shared housing alongside other young people with care needs and animals to care for. This supportive community helps one another and is backed by a dedicated team of professionals who enable them to live life on their terms.

As a full-time wheelchair user, Esther relies on specialized seating to maintain a well-positioned and comfortable posture throughout her day, thereby preventing complications and improving her quality of life. Jan Warnke from the RAS Team has been a trusted partner in her journey for more than a decade. He is not just her orthopedic technician—Jan understands Esther’s unique movement patterns, posture, and communication cues at a level that comes only with years of care, trust, and deep professional expertise.

Jan Warnke is a certified orthopedic technician with over twenty years of experience specializing in seating and positioning for individuals with complex physical needs. Known for his patient-centered approach, Jan combines extensive technical knowledge with empathy and dedication, always aiming to enhance both function and overall well-being. He focuses on creating customized seating solutions and has been an early adopter of innovative 3D printing technologies in the field of orthopedic care.

With this strong foundation of trust and expertise, understanding Esther’s medical background is crucial for tailoring the best seating solution to her specific needs.

Being able to sit is game-changing

Esther’s scoliosis creates an unusual spinal curve that complicates her posture. Along with cerebral palsy, this leads to muscle tone imbalances—low tone in her trunk and head but higher tone in her limbs, which affects her ability to control movements. The rare costoiliac impingement syndrome adds a layer of complexity, causing pain and sensitivity in the pelvic and rib area that traditional seats struggled to accommodate.

And the situation was critical. Doctors worried about whether a suitable seating system could be created for her, given these challenges. Jan highlights that sitting is not just a physical necessity—it’s also a social and emotional one. Doctors were unsure whether Esther could even get a seating solution that worked.

In Esther’s case, her scoliosis, spasticity, and rare costovertebral issues made seating extremely difficult. But Jan knew that finding a working solution was critical—not just for her health, but for her sense of self and her connection to the world around her.

Jan’s focus was broader than just posture. He emphasized:

“When you can sit upright, without pain, in a balanced and supported position, it changes everything. It’s about being able to take part in life—to be face to face with others, not always tilted away or in discomfort. Good seating enables communication, interaction, and dignity.”

Challenges with traditional seating

For years, her family and care team had tried to create seating solutions that would keep her stable, supported, and comfortable. However, as her needs became increasingly complex, it became harder to find a seat that suited her.

“She was always slipping, even in custom-made seats,” recalls orthopedic technician Jan Warnke. “You could see she wasn’t positioned well. And you could also tell it in her mood.”

The constant adjustments and compromises took their toll. Her seats were rebuilt or adapted again and again. And still, her mother worried. Would they ever find something that truly worked?

Esther’s traditional seating solution came with several significant issues:

- Poor fit: The carved foam seat did not fully match her spinal curves, resulting in pressure points and discomfort.

- Pain and skin risks: Constant pressure and friction increased the likelihood of wounds and infections.

- Postural support: Esther needed to wear a corset—starting with a soft brace and later a stiff PE corset—to hold her posture, but these were uncomfortable, and compliance was low.

- Durability and hygiene: The foam would compress over time, losing support, and could trap moisture, leading to hygiene problems.

- Limited dynamic comfort: Traditional foam was soft but lacked stability, and it didn’t allow for dynamic movement, making it harder to stay comfortable during prolonged sitting periods.

These factors made it difficult for Esther to sit comfortably and safely, limiting her quality of life. But that is not all.

Jan explained that traditional foam seats are constructed by gluing multiple layers of foam together—a method that makes it difficult to shape the seat accurately and often results in weak points at the joints. Where the glue is applied, it can create a hard layer that reduces comfort, limits ventilation, and increases the risk of pressure points and skin irritation.

Rethinking posture in complex cases

In her traditional foam seat, Esther had to rely on a corset to hold her posture. The seat alone couldn’t offer the support she needed, especially given the complexity of her scoliosis—her spine was twisting and collapsing to one side. The corset was meant to stabilize her torso, but in practice, it came with significant trade-offs.

Over the years, Esther and her mother had tried several different corsets, each time hoping for better comfort and positioning. But none of them really worked. Some were too rigid, causing pressure points and pain. Others weren’t supportive enough, or their presence made her sitting posture worse. The corset limited her mobility and made it harder for her to relax, which affected her overall well-being.

- It guided her spine into a more upright and balanced position, without forcing it.

- It provided enough structure to keep her from collapsing sideways, even without a corset.

- It gave her more freedom of movement and noticeably better comfort.

Digital workflow

We know from experience that transitioning to a fully digital workflow is the biggest obstacle for many. Additive manufacturing marks a shift—from handcrafted, one-off designs to the ability to fine-tune even the smallest details in a 3D design program, taking accuracy to an entirely new level. The good news? It’s not as difficult as it may seem.

Here are the three key steps:

- Data capturing:

For Esther, a vacuum bag was the most important tool. In addition, pressure mapping, X-rays, and a general understanding of the patient’s condition were essential. - Scanning and analysis:

The vacuum bag was scanned, and the data analyzed. - Model preparation:

The model was adjusted by adding softness and hardness in the right places to provide the appropriate support.

Let’s look at how this process worked in Esther’s case.

Vacuum bag

Jan explains that the vacuum bag plays a crucial role in designing the seat. While it’s commonly used to capture the user’s shape, he also uses it as a sculpting tool, adjusting pressure and contours while Esther is seated. This hands-on process enables him to craft a seat that provides immediate comfort, with the ideal balance of support and softness tailored to her body. It forms the foundation for a truly individualized solution that minimizes pressure points and supports her posture throughout the day.

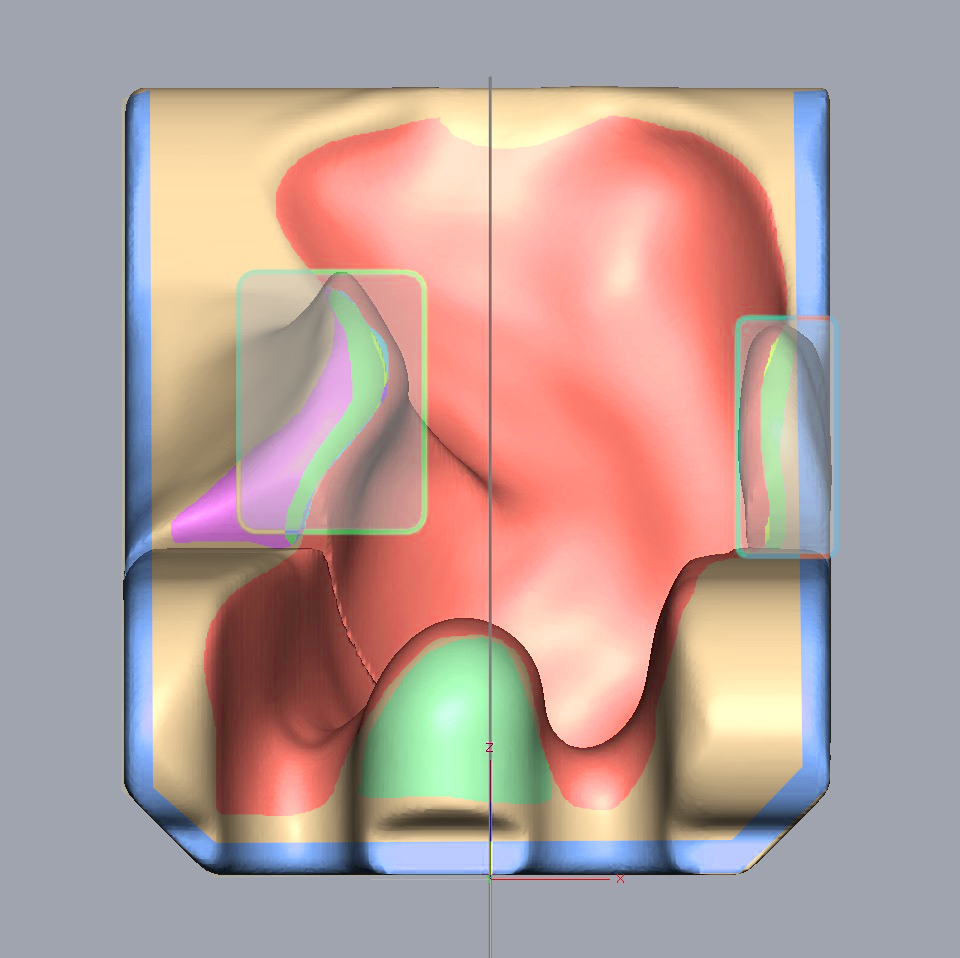

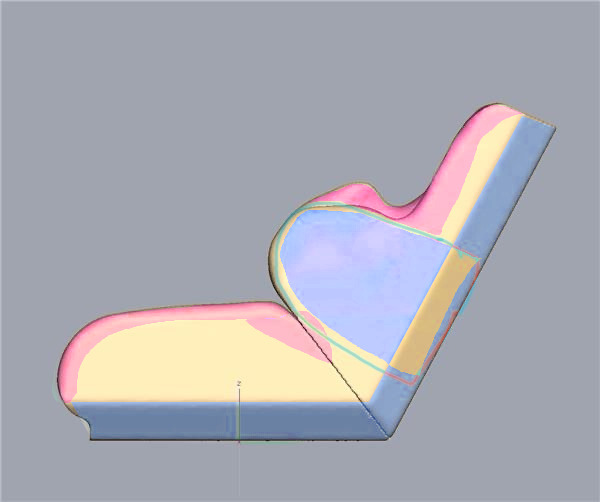

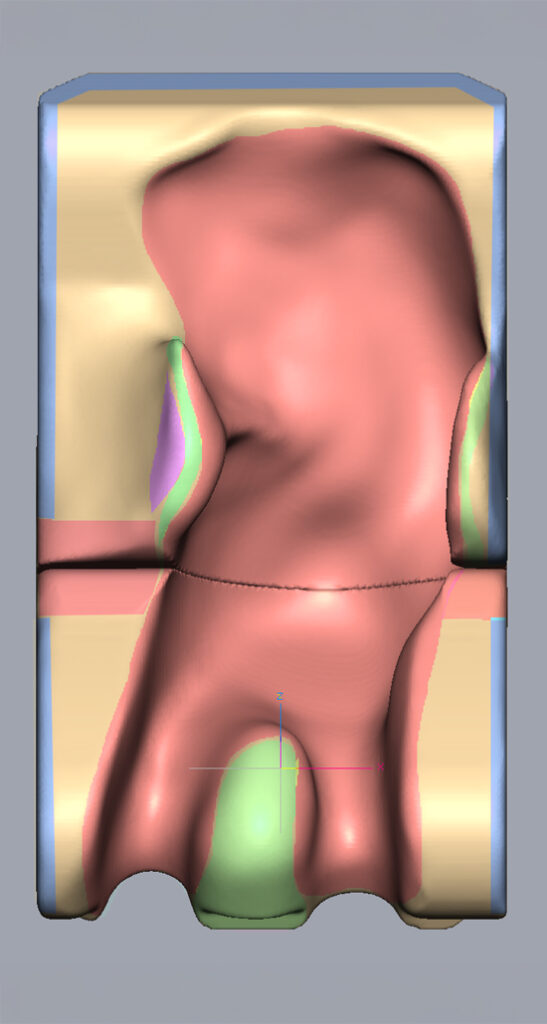

Scanning and preparing the 3D model

Once the vacuum bag has been sculpted into the perfect shape, it is scanned to create a digital model. But that’s only part of the equation. “Before we can finalize the design, we need to know the dimensions of the wheelchair,” Jan explains. “The seat must fit perfectly—not just to Esther’s body, but also to the frame it will sit on.” This attention to detail ensures that the final 3D-printed seat is not only comfortable but also fully compatible with Esther’s mobility device.

Designing support with precision and care

The final preparation is where Jan’s expertise truly comes into play—this is when he translates years of clinical experience into precise design choices. Based on the scanned impression of Esther’s relaxed but aligned posture, Jan defines exactly where softer and firmer zones should be placed in the 3D model. This is where the digital workflow makes a huge difference: he can control every single pixel of support.

For Esther, that precision was essential. The outer layer of the seat was printed with a soft 1.5 cm foam to provide cushioning, while the deeper layers gradually became firmer to stabilize her spine, gently stretch the scoliosis curve, help her breathe more easily, and slow the progression of her condition.

One of the secrets is the patented smooth gradient transition. It offers a homogeneous and breathable structure with no hard glue lines or stiff edges. Unlike traditional foam seats, which are made by gluing layers together—often leading to uncomfortable transitions and poor breathability—this seat is printed in one piece.

Jan explains that this new type of seat is not static. “She can move her shoulders, stretch her arms—it’s dynamic,” he says. “At the same time, it acts like a molded support and a brace in one. It follows her body exactly, giving support where she needs it, without restricting her.”

After finalizing the design, the next step is printing.

Final preparation and 3D printing

RAS Team is a customer of our 3D print service. Once Jan has finished implementing the zones in the 3D model, we make the final adjustments to the file to ensure a successful print.

In our print service, we use several Embrace SeatMakers—specialized production units designed for manufacturing Programmable Foam® seating. Printing in soft materials like our soft TPU is a complex process, which is why all components—REALvision Embrace, CreaTech material, and the Embrace SeatMaker—are carefully selected to work together in producing high-quality seating aids.

The good news? Everything we use in our print service is available to customers. So if RAS Team—or any other print service customer—decides to invest in their own system, they can expect exactly the same results, along with ongoing support from our skilled team.

Back to Esther’s seat: For molded seats like hers, printing takes approximately 48 hours, and post-processing is minimal. That means it’s ready for final fitting shortly after printing.

From doubt to daily comfort

Once the final seat was assembled and covered, everything changed.

Esther’s mother had been a little skeptical at first. The shape was unfamiliar, and the whole approach—3D printing a seating aid—was new. But she already knew the parents of Bernd, another young wheelchair user who had received a Programmable Foam® seat. Seeing the impact it had on Bernd gave her confidence.

And when Esther’s seat was finally fitted, any remaining doubt disappeared.

“With the cover on, the seat just made sense,” Jan says. “Suddenly, it worked perfectly.”

For Esther and her caregivers, the benefits were clear right away:

- Her skin issues improved significantly, thanks to better pressure distribution, ventilation, and the elimination of irritating glued layers.

- The seat stayed dry and clean, even after long hours, thanks to its breathable, non-absorbent design.

- Ventilation helped regulate heat, improving comfort, especially on warmer days.

- Most importantly, the shape now gave her the exact support her body needed—respecting her asymmetries, gently encouraging better posture, and keeping her stable without pressure points.

In Jan’s words, this was the moment where everything they had worked toward became visible: a functional, breathable, and clean seating solution that supported Esther not just physically but also in her everyday life.

A turning point for Esther

When Jan first joined the case, the outlook was uncertain. Esther’s scoliosis had progressed to the point where her doctors questioned whether a sitting solution was even possible. Previous seats caused pain, skin problems, and left her exhausted.

But just four months after receiving her new 3D-printed seat, the change is unmistakable. Her skin is healthier. The seat remains dry and ventilated, even after extended periods. The custom shape and gradient structure provide her with the right support in the right places, improving her posture, breathing, and overall comfort throughout the day. “She’s more alert, more active, and smiling much more,” Jan said.

And for the first time in all the years Jan has known Esther and her mother, they both say they are completely satisfied with the seating. That kind of feedback is rare, and a clear sign that the solution finally matches the need.

The seat has also opened new doors: Esther has recently moved into a group home with daily support—a step that wouldn’t have been possible without the stability and comfort her new seat provides.

Esther’s posture has changed. Her daily life has changed. And perhaps most tellingly of all—

Esther’s new seat makes her smile a lot.